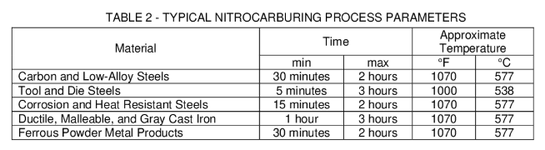

Quite familiar with nitriding (SBN-QPQ) being in the oil and gas manufacturing industry and managing our supply chain. For those wondering, most procedures I have seen call for a bath temperature of 1050-1100F for 60 to 120 minutes. We routinely treat 410 and 17-4 stainless steels.

In all, I have no concerns with nitriding a Tikka action assuming you are using a reputable vendor. I'm actually going to have someone local we use for work do mine. I'm a bit torn on doing a barrel and have actually reached out to PBB for feedback. I do know the shop I have been talking with does hundreds of barrels every single day. Most of their work is actually for the firearm industry.