Hmmm, I used a Hornady match 6gt die with the 22 cal 90atip stem on my 22gt, no issues. That's only dropping 0.019" bullet diameter, you're dropping 0.041". I use my 65saum seater to seat 6mm Saum rounds without issue, RCBS match master dies. I have not disassembled that die to see if the stem is interchangeable as it's part of the micrometer top.

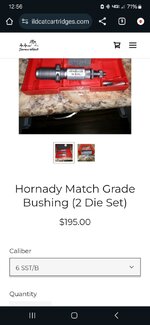

Here's an idea, check and see if you can possibly get a 6SST sliding inner sleeve, as it should fit the 6mm Stem better. These are custom dies from Sherman Wildcat, but Hornady makes them. The 6sst is based upon and slightly shorter improved Saum, so the body of the case will be 0.025 smaller at the shoulder/body junction, but it's still a 30° shoulder.

View attachment 722301