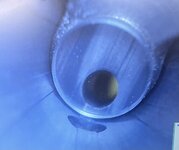

This seems like a really good idea and probably works very well too. Could you describe the process you used? Looks fairly self explanatory, but you probably learned some tricks along the way.I also thought the Solo 300 ball detent spring was causing too much friction in the upper, so I clipped a few coils off the spring and created a bedding for the detent ball into the upper with some Devcon epoxy. It gives a much more solid lockup and moves more smoothly. This was on a Cross Machine Tool UPUR-3A, since I wanted a right side charging handle (I also drilled and tapped Solo BCG to move the handle to the right side).

View attachment 685049View attachment 685050

Now that Solo will be making their own dedicated uppers, I suggested that they build a feature like this into to the machining. I don't know yet if they will, but if not, this could be another way to do it. I'd like to try it out.