OneSkinnyHunter

Lil-Rokslider

Aww, gotcha thank you - not enough coffee todaythe Solo carrier is already "chopped". He's referring to using a standard bolt carrier.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Aww, gotcha thank you - not enough coffee todaythe Solo carrier is already "chopped". He's referring to using a standard bolt carrier.

Please explain more, sir. I need to do this!Great minds and well, you know!View attachment 644474

How are you planning to add a bolt handle to the carrier? I've looked at pictures of those carriers but wasn't sure if there was enough material there to drill and tap for a handle. I'm curious about what solution you find, how easy it is and how well it works. Could be a good system if you can get that to work well.Wow, these NFA lowers and LPK's are insanely light. Just assembled one, 4.2 oz stripped, 6 oz with LPK (no grip/buffer tube). I also removed some material from the hammer/sear notch, but didn't want to go too slim, assuming the polymer will wear slightly, but got the trigger decent.

Add a Hogue grip, A2 buffer tube and Farrowtech and you have a ~12 oz complete (straight pull) lower. I also used a set screw to hold the rear takedown detent; it's easy with the polymer lower because the set screw taps itself when you screw it in; it's tight - feels secure.

I'm also considering a DIY straight pull upper; got the aluminum BCG from Outdoor Sports USA that weighs 5.9 oz ($100); you could cut that off and drop an oz or two, then mill out an Aero Precision slickside and be under the weight of the Solo 300, for about $180 in parts.

I know many of these parts are far from mil-spec, and probably wouldn't last very long, but I don't think I'll shoot this rifle 1000 times in my life, so...

How are you planning to add a bolt handle to the carrier? I've looked at pictures of those carriers but wasn't sure if there was enough material there to drill and tap for a handle. I'm curious about what solution you find, how easy it is and how well it works. Could be a good system if you can get that to work well.

It looks like it worked okay with your DSA? It's holding up well? Looks like the DSA side cutout might be similar in depth to PistolPete's carrier, so it might work fine(?).Well done, Pete! You have a solid blueprint for an ultralight blaster.

Below are photos of two carriers that are threaded for knobs. Hopefully this helps people out. The full-length one is a DSA aluminum carrier with left-side charge that I did myself; the chopped carrier is a steel version with right-hand charge that gunsmith Ned Christiansen did.

Unless you're an advanced hobbyist, I suggest you have a machinist/gunsmith do the work. The results will turn out better.

Please post pics of the detent key. That sounds like a cool solution.It looks like it worked okay with your DSA? It's holding up well? Looks like the DSA side cutout might be similar in depth to PistolPete's carrier, so it might work fine(?).

Although more expensive, one advantage to using the Solo is the "detent key" that replaces the gas key with that system, which helps keep the bolt locked. Another advantage is the bolt carrier is designed specifically as a side charger with plenty of metal in the threaded portion. I'll post a pic of that carrier as it will explain that better.

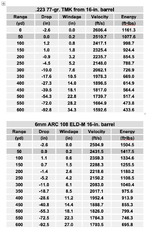

I’d be interested in your experience with the 6 ARC as well.Yes, I've built a straight-pull AR in 6mm ARC. It's easy to do. You're in WA, where .224-caliber bullets are not legal for big-game, so that would be a good option. PM me and I'll send you an article I wrote. Be warned, however, that most people find the Grendel-based cartridges to be harder to cycle.

I think I'd opt for a couple of holes drilled in the CF tube with a loop of paracord run through, though I haven't done that yet, myself.I found some inexpensive thread protectors for the barrel end threads on Amazon. The more common ones are steel, but I was able to find aluminum with a bit of searching. Just note that the threads can be either 1/2" or 5/8" depending on the barrel. Another option to protect the threads is simply a couple wraps of e-tape. My current project is sitting at 3 lbs, 14 oz, no mag, with a scope.

Options for front sling attachment? I'm thinking either drill a hole in the carbon forearm tube or modify a gas block (cross drill a hole) where the gas tube attaches. Thoughts?