Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ultralight Ultralight Rifles

- Thread starter Thegman

- Start date

I hope you're right. Coming in on the tail end of this, that barrel being available is what pushed me over the edge.

No issues messing around with blocking a gas port.

Streamlined good looks.

Makes the KAW PCC carbon fiber handguard fit without fiddling.

And, now I know it shoots more accurately than I need to ethically take deer where I hunt.

No issues messing around with blocking a gas port.

Streamlined good looks.

Makes the KAW PCC carbon fiber handguard fit without fiddling.

And, now I know it shoots more accurately than I need to ethically take deer where I hunt.

From my conversation with them, I'm almost positive they will be making more.Anyone know if Shaw is going to do another run of portless lightweight barrels?

A buddy tried mine and is all-in on the concept.

From my conversation with them, I'm almost positive they will be making more.

Can you poke them about a 6mm option?

My preference is 6x45. I’m curious if they can build it light and low cost needing to bell up to a 5/8 threading.

Satern sounds too busy/uninterested.

They make adapters. My Polonium works on 6mm as well, and it's direct thread thingy is 1/2 threading.Can you poke them about a 6mm option?

My preference is 6x45. I’m curious if they can build it light and low cost needing to bell up to a 5/8 threading.

Satern sounds too busy/uninterested.

My spaghetti contour 6x45 is threaded 1/2x28.They make adapters. My Polonium works on 6mm as well, and it's direct thread thingy is 1/2 threading.

BREAKCONTACT

FNG

- Joined

- Jul 15, 2024

- Messages

- 92

I'll mention the interest in 6x45. They seem to be receptive to new ideas. After getting the 223 profile down, it might be easy to slightly scale up the profile for 6mm and add a small run of them(??). I also think 1/2xCan you poke them about a 6mm option?

My preference is 6x45. I’m curious if they can build it light and low cost needing to bell up to a 5/8 threading.

Satern sounds too busy/uninterested.

For the UL-UL historical record, we all owe @StupidLightweight a big thanks for getting Shaw going on these barrels. He was the one who was instrumental in guiding the design into what they now make. Honestly, probably never would have happened without his input.

Uh, yeah... 6x45 - and 1/2x

Last edited:

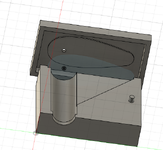

That's super cool. Would be interesting to hear more about how you make them.Prototype carbon fiber copy of the farrowtech with the flashing removed. I'll probably make some mold changes and redo it after the holidays. It's exactly 40g as it sits.

I had a Christensen Mesa in 300prc that was threaded 1/2x28, so any caliber under 30 is possible. I wasn’t able to catch the Shaw, I’d be an early adopter of another 6x45 though.I'll mention the interest in 6x45. They seem to be receptive to new ideas. After getting the 223 profile down, it might be easy to slightly scale up the profile for 6mm and add a small run of them(??). I also think 1/2x45 would be completely fine. Kimber uses 1/2x45 on 30 caliber rifles, even 300 WM. My X-Caliber 30 HRT is 1/2x45 as well. Not optimum, but seems okay-ish even for 30 cal.

For the UL-UL historical record, we all owe @StupidLightweight a big thanks for getting Shaw going on these barrels. He was the one who was instrumental in guiding the design into what they now make. Honestly, probably never would have happened without his input.

BREAKCONTACT

FNG

- Joined

- Jul 15, 2024

- Messages

- 92

It's 3 part 3d printed mold split along the long axis of it on either side of the webbing peice with an endcap where the butplate is formed, I need to make some changes to the model when I get time and I'll share it with anyone that wants it, I had to do too much sanding for fitting it together.That's super cool. Would be interesting to hear more about how you make them.

Added a screenshot of the model for clarity, there's another half that's the mirror of the shown half to clamp around the buffer tube and its located to the end using a bolt.

Attachments

Last edited:

Are you printing tube and butt plate?It's 3 part 3d printed mold split along the long axis of it on either side of the webbing peice with an endcap where the butplate is formed, I need to make some changes to the model when I get time and I'll share it with anyone that wants it, I had to do too much sanding for fitting it together.

Added a screenshot of the model for clarity, there's another half that's the mirror of the shown half to clamp around the buffer tube and its located to the end using a bolt.

BREAKCONTACT

FNG

- Joined

- Jul 15, 2024

- Messages

- 92

No, I just used the rifle reciver extension as the core, after building up a layer of release agent and putting modeling clay around the end boss, those prints are the mold for a carbon fiber layup. After people poster their farrowtech stocks breaking I figured I'd try making something similar out of CF so it would be stronger, and it definitely is. I was beating on it with a rubber mallet and twisting it with as much force as I could to get it off the buffer tube after it cured. That thing is rock solid, and I can probably cut another 10g or so of material off of it.Are you printing tube and butt plate?

I wonder how well it would work to make something similar with a CF tube and CF plate, using epoxy to attach the rear and support piece to the tube(?).No, I just used the rifle reciver extension as the core, after building up a layer of release agent and putting modeling clay around the end boss, those prints are the mold for a carbon fiber layup. After people poster their farrowtech stocks breaking I figured I'd try making something similar out of CF so it would be stronger, and it definitely is. I was beating on it with a rubber mallet and twisting it with as much force as I could to get it off the buffer tube after it cured. That thing is rock solid, and I can probably cut another 10g or so of material off of it.

That said, there's a lot to be said for the stocks Smoke Composites build.

BREAKCONTACT

FNG

- Joined

- Jul 15, 2024

- Messages

- 92

You could easily do that and it would be still stronger than those farrowtech ones. Just build a fillet of thickened epoxy along each seam where you bond them together and it would be plenty strong.I wonder how well it would work to make something similar with a CF tube and CF plate, using epoxy to attach the rear and support piece to the tube(?).

That said, there's a lot to be said for the stocks Smoke Composites build.

Got outside today. The Shaw barrel likes AAC 77g OTM. Shot 10 shots off a rest into a tiny bit under 2" at 100. One ragged hole at 50.

I'm happy with this. Very happy. I'll be loading up some TMK's to hunt with.

I shot everything inside 2moa with mine while testing hand loads. Right out the box. Total of about 30 rounds. It’s a shooter for sure. Same experience at 50 to zero scope with 77otm BH - big ragged hole.

That said - it’s no more accurate than my 65.00 BCA pencil barrel. At least not in my hands…yet.

I single fed 77tmk loaded at 2.425” and 3 went right at an inch at 100, average speed 2830 with lever. I don’t know what I’ll do with this information, but it’s cool to know. I’ll be able to put these in the wife’s Christmas present(Howa mini I just scooped up).

Similar threads

Featured Video

Latest Articles

- How Old Was He Really? Big Buck Hunters Talk Age vs. Score

- Banning Hunting Technology in Idaho?

- Best Gear of the year Rokslide staff edition 2025 Article

- Hunting Gear: Insights from Western Hunting Expo

- Black Diamond Alpine Start Insulated Hoody Review

- Tenacity Firearms with Andrew Whitney

- The Thrill of Moose Hunting with Henry Ferguson

- Final Rise Upland Hand Muff Review

- Kodiak Deer Hunt Round II

- Killing a Timber Giant