Jake Larsen

WKR

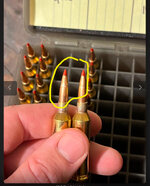

Prepping the next test.

I’ll be focused on verifying drop data with the tumbled pieces, and monitoring velocities.

The “no prep” seated with substantially more force (which I expected) and left a small dent in the circumference of the bullet.

View attachment 805647

View attachment 805648

I found the exact same thing with Alpha brass. Used it for two different cartridges now. There’s significant tension if it’s not run across a mandrel. How consistent it is from piece to piece? Who knows…would need one of those computerized tools to measure seating pressure

Sent from my iPhone using Tapatalk