Get some 50/50 Ballistol and water for lube and swabbing. Run along time without swabbing between shots at the range. Hunting, I use mink oil lube or similar, so it doesn’t dry out.Haha- no. I have been able to do 20+ shots before without swabbing.

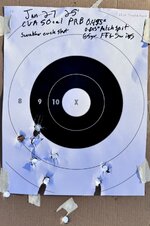

Spit patch swabbing between shots yesterday-

View attachment 985719

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Patched roundball range day

- Thread starter 30338

- Start date

- Joined

- Oct 22, 2014

- Messages

- 14,682

I tried to do two 10 shot groups with PRB’s and this CVA. @longrangelead stated that this barrel had been left loaded for about 15 years. Due to the barrel issue, I cleaned it well and could feel a “ring” or really rough spot right where the bullet would sit.

First 10 shots would be without swabbing between shots. First couple went ok, the second load was only a bit more difficult to seat. But, at #3 it became very difficult to seat and only got worse. By shot 5 or 6 I had to use the tailgate to seat the ramrod all the way. The shots also got worse. Shots 7 and 8 didn’t hit the IPSC backer.

These were pre-lubed patches .015” thick and .490” balls. 65gr FFG Swiss.

Looking at the target when I went to pull it, the two balls hit the head. This continues the trend of it shooting way high when it gets Fowled.

I stopped at 8 as they were off the paper. Swabbed with spit patches and started the second group of 10 that were going to be swabbed between every shot. These were spit patches with .490” balls- 65gr FFG Swiss. Only made it to shot number 2, as the end of the ram rod came off-

Went home, put a bunch of super glue on the end of the ram rod (glueing myself to everything in the process) and shoved it back down. Got it out and continued today-

What’s interesting is when the swab patch was very tight at the breach, that’s when the shots were off. The times I swabbed and it felt much smoother, that’s when the shots were in the black (the first two shots after the heavy swabbing were both in the black). The nasty spot in the barrel was cutting the swab patches.

Then I tried the same .015” spit patch with a .495” ball, same 65gr FFG. While they were much harder to start, the tighter ball/patch combo did seem to help keep the fowling not so aggressive in the patches.

The group was significantly better, but again when the swabbing was rough and tight- the next shot was generally one of the lower ones.

I’ll keep playing with it until the Flintlock comes in, but the barrel needs some attention.

First 10 shots would be without swabbing between shots. First couple went ok, the second load was only a bit more difficult to seat. But, at #3 it became very difficult to seat and only got worse. By shot 5 or 6 I had to use the tailgate to seat the ramrod all the way. The shots also got worse. Shots 7 and 8 didn’t hit the IPSC backer.

These were pre-lubed patches .015” thick and .490” balls. 65gr FFG Swiss.

Looking at the target when I went to pull it, the two balls hit the head. This continues the trend of it shooting way high when it gets Fowled.

I stopped at 8 as they were off the paper. Swabbed with spit patches and started the second group of 10 that were going to be swabbed between every shot. These were spit patches with .490” balls- 65gr FFG Swiss. Only made it to shot number 2, as the end of the ram rod came off-

Went home, put a bunch of super glue on the end of the ram rod (glueing myself to everything in the process) and shoved it back down. Got it out and continued today-

What’s interesting is when the swab patch was very tight at the breach, that’s when the shots were off. The times I swabbed and it felt much smoother, that’s when the shots were in the black (the first two shots after the heavy swabbing were both in the black). The nasty spot in the barrel was cutting the swab patches.

Then I tried the same .015” spit patch with a .495” ball, same 65gr FFG. While they were much harder to start, the tighter ball/patch combo did seem to help keep the fowling not so aggressive in the patches.

The group was significantly better, but again when the swabbing was rough and tight- the next shot was generally one of the lower ones.

I’ll keep playing with it until the Flintlock comes in, but the barrel needs some attention.

ResearchinStuff

WKR

Have you tried shooting it on a moist day yet? High humidity, foggy, snowing hard, or better yet rainy?

insanelupus

WKR

- Joined

- Sep 2, 2015

- Messages

- 657

Form,

I'm far from an expert, but was trained under the tuteludge of one who was. He built the .54 that I took this buck with several years ago at 75 yards. First time that rifle had been hunted in almost 30 years and my mentor died within a month of this photo being taken. Best present I could have given him. I've learned a little from others mistakes since then.

One word of caution, if you have to hammer that ram rod home with the tailgate, probably best to clean. Little good will come of doing so and often some form of damage can result. Sometimes, we have to accept and conform to the limitations of the tool we are using, or find a tool that better conforms to our standards.

Those pre lubed patches are convenient, true. As you have discovered, the tighter the patch/ball, typically the better the group. But powder fouling is a thing. Good Swiss powder (if it can be found, tough at the moment) is a gift and second to none. Running your patch material (100% cotton) through a hot wash cycle and drying is supposed to be beneficial, which means cutting (pre cut or at the muzzle) and lubing them . And experimenting with lube (hey, don't be weird here) is a good idea. Mink oil is often touted and that's been my go to for the rifle pictured. My mentor used a home brew of sheep tallow and beeswax, perhaps with a little linseed oil (memories fade). I asked once about bear grease and his experience indicated it is too thin. There is a balance in patch lube regarding thickness and viscocity I'm still learning.

I've purchased a .58 I need to repair a little and then get online next year. The rifles my mentor built are relegated to terrain I can navigate without falling these days, but the elk don't usually live there! Thus the purchased .58. I'll be playing with lube, ball size, and powder charges, provided I can find more 2F Swiss.

One thing friends have found helpful and I believe it was mentioned, a fiber wad over your powder charge before the PRB is seated. Research I've done indicates going up a caliber is helpful too (I'll be using .62 wads). Lowers extreme spread and has helped accuracy with several I know using conicals, but does the same for PRB.

My experience has all been with slow twist barrels for PRB and the .58 I have is basically a sporterized Remington 1863 Contract rifle that was never actually produced. An Antolio Zoli creation of the 70s. Complete with shallow rifling, 3 groove short barrel, and I've found multiple twists listed from moderate that should be PRB fine to slow and no good for conicals, which I doubt.

Rarely with a muzzlleloader will there be a generic secret sauce. More than modern rifles, each is a rule into its own and requires experimentation.

My mentor told me there have been and are many muzzleloaders capable of very good accuracy. He built many of them over his lifetime. But not every shooter is or has the patience to find it he told me. But the myth that PRB is not capable of small groups at 100 yards is just that, a myth. Not all muzzleloaders are capable of it, but he always reckoned there were fewer shooters capable of finding the necessary combo than there were muzzleloaders.

I'm far from an expert, but was trained under the tuteludge of one who was. He built the .54 that I took this buck with several years ago at 75 yards. First time that rifle had been hunted in almost 30 years and my mentor died within a month of this photo being taken. Best present I could have given him. I've learned a little from others mistakes since then.

One word of caution, if you have to hammer that ram rod home with the tailgate, probably best to clean. Little good will come of doing so and often some form of damage can result. Sometimes, we have to accept and conform to the limitations of the tool we are using, or find a tool that better conforms to our standards.

Those pre lubed patches are convenient, true. As you have discovered, the tighter the patch/ball, typically the better the group. But powder fouling is a thing. Good Swiss powder (if it can be found, tough at the moment) is a gift and second to none. Running your patch material (100% cotton) through a hot wash cycle and drying is supposed to be beneficial, which means cutting (pre cut or at the muzzle) and lubing them . And experimenting with lube (hey, don't be weird here) is a good idea. Mink oil is often touted and that's been my go to for the rifle pictured. My mentor used a home brew of sheep tallow and beeswax, perhaps with a little linseed oil (memories fade). I asked once about bear grease and his experience indicated it is too thin. There is a balance in patch lube regarding thickness and viscocity I'm still learning.

I've purchased a .58 I need to repair a little and then get online next year. The rifles my mentor built are relegated to terrain I can navigate without falling these days, but the elk don't usually live there! Thus the purchased .58. I'll be playing with lube, ball size, and powder charges, provided I can find more 2F Swiss.

One thing friends have found helpful and I believe it was mentioned, a fiber wad over your powder charge before the PRB is seated. Research I've done indicates going up a caliber is helpful too (I'll be using .62 wads). Lowers extreme spread and has helped accuracy with several I know using conicals, but does the same for PRB.

My experience has all been with slow twist barrels for PRB and the .58 I have is basically a sporterized Remington 1863 Contract rifle that was never actually produced. An Antolio Zoli creation of the 70s. Complete with shallow rifling, 3 groove short barrel, and I've found multiple twists listed from moderate that should be PRB fine to slow and no good for conicals, which I doubt.

Rarely with a muzzlleloader will there be a generic secret sauce. More than modern rifles, each is a rule into its own and requires experimentation.

My mentor told me there have been and are many muzzleloaders capable of very good accuracy. He built many of them over his lifetime. But not every shooter is or has the patience to find it he told me. But the myth that PRB is not capable of small groups at 100 yards is just that, a myth. Not all muzzleloaders are capable of it, but he always reckoned there were fewer shooters capable of finding the necessary combo than there were muzzleloaders.

Attachments

You need to get a new ram rod. At least the wood and pin the end on. I wouldn't trust any kind of glue. You can buy wood blanks from muzzleloader supply dealers. I make up a spare or two. A real range rod is a real plus.

Search - Track of the Wolf

Muzzle Loading & Black Powder Guns Kits, Parts, Accoutrements, Rendezvous Gear & Primitive Americana.

www.trackofthewolf.com

- Joined

- Oct 22, 2014

- Messages

- 14,682

You need to get a new ram rod. At least the wood and pin the end on. I wouldn't trust any kind of glue. You can buy wood blanks from muzzleloader supply dealers. I make up a spare or two. A real range rod is a real plus.

Search - Track of the Wolf

Muzzle Loading & Black Powder Guns Kits, Parts, Accoutrements, Rendezvous Gear & Primitive Americana.www.trackofthewolf.com

Haha. They were ordered within 5min of it happening.

BBob

WKR

5lb of Swiss inbound. Guess I’m committed

- Joined

- Oct 22, 2014

- Messages

- 14,682

5lb of Swiss inbound. Guess I’m committed

Man that’s a pretty good day of shooting…

Grin.

FrontierGander

WKR

With Swiss costing $60 a lb now, Im sure glad i make my own stuff lol.

ihookem

Lil-Rokslider

Where do you get your other two ingredients? I have the charcoal already that I made myself.With Swiss costing $60 a lb now, Im sure glad i make my own stuff lol.

FrontierGander

WKR

Just off of Amazon. Bought them a handful of years ago.Where do you get your other two ingredients? I have the charcoal already that I made myself.

ihookem

Lil-Rokslider

Do you prefer a brand of sulphur or potasium nitrate?Just off of Amazon. Bought them a handful of years ago.

FrontierGander

WKR

No specific brand at allDo you prefer a brand of sulphur or potasium nitrate?

HighUintas

WKR

- Joined

- Feb 2, 2020

- Messages

- 4,297

From my and common knowledge would say they're ok but the damaged/cut parts could potentially be detrimental to accuracy.

I have not seen a single person, anywhere, that has said it doesn't matter if patches are cut/damaged after shooting.

I haven't tested it in a controlled enough manner myself to say for sure, but I did have a gun that cut patches due to rough/raised burrs on the edges of the lands from crap machining. After fixing that, the accuracy seemed better. Prior to fixing it I'd get occasional fliers way out of the rest of the group. Like something obviously wrong ... Not cherry picking and 3rd groups.

I would like to see a controlled test though. I think to a degree it makes sense. If there is gas leakage around the patch or unequal friction between patch and bore on one side from damage, I would think that could cause big variation in pressure, etc.

From all I've been able to find, people seem to agree it doesn't matter as long as all sides are covered. I believe there have been tests to determine if it matters.... Even if the sprue being up/down/off center matters, and those said it doesn't. But I can't remember who tested this and don't have a link.I was thinking about this. Does the latch need to be perfectly centered? Or does it just need to cover the ball so that it is contained?

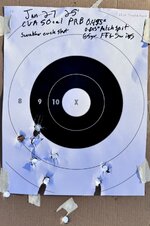

Shot a few rounds with the borrowed rifle late this afternoon. Light wa slow, and it was hard to center the bull, but…

There is definitely a tight spot in front of the breach, going to give it a good scrubbing tonight.

With that, this thing really wants the bore swabbed between shots. 1, it gets very hard to seat the patch and ball past that “ring” if you don’t swab the shots go haywire consistently.

View attachment 988898

Three different things going on here.

These were shot intermixed- blue are all slit swabbed between shots. Yellow is one dry swab between shots, red is no swabbed between shots. I shot a couple shots swabbing (blue), then didn’t swab (red), then swab again (blue). Then, dry swab (yellow), then swab- (blue). Etc.

Not swabbing between shots consistently has the shot going 4-6” high.

View attachment 988899

Made a sight adjustment up, swabbed the barrel, and fired one at 100 yards kneeling against a tree for grits and shins- barley clipped.

View attachment 988900

A few things:

Tight spot in breech after shooting- swiss has the potential to cause a worse fouling ring in the bottom, for whatever reason. I usually use schuetzen which is dirty as all hell in my gun (but does not make a hard ring) and tried swiss this year. After a couple shots, yes there's a crazy hard ring in the bottom and all other who've experienced this agree that when that hard ring forms your accuracy goes to crap... I think it probably changes pressure if it doesn't damage the patch. I have experienced the issue. I do not know how to prevent it other than swabbing it out.

Shots being lower on clean bore - yes a clean bore produces lower MV and I guess lower pressure. I have noticed this with mine with certain loads. With a super tight combo in my two guns it seems to not make as much difference between clean/fouled bore. This is where having a tight enough patch/ball combo and a good lube helps. If it's tight enough, and the patch is moist enough, it will basically wipe the bore each time you load and give the same bore condition each time. I do this because taking the time to swab drives me nuts.

Patches- the prelubed are handy, but using a super tight weave and very strong material supposedly works best for accuracy. There are none of this quality that are prelubed that I know of. Using tighter weave that is stronger material means no gas blow by, which is supposedly beneficial to accuracy. Idaholewis has shown it a couple times in his videos. He'll use precut patches that are thin, but he will double patch... Put a patch over the powder below the patched ball which protects the integrity of the patch on the ball. I haven't tested this myself because I went straight to loading the tightest load I could from the get go. However, I have seen accuracy degrade with damage patches or completely blown patches.

Look into minute men patching. Tightest and toughest stuff I've found. Wash regular cycle, rinse twice, dry medium. Cut strips and then cut at the muzzle using spit for lube to make it easy. https://www.theminute-menpatches.com/ try the 0.018 and 0.020.

Could also find some tight weave duck canvas that measures 0.018-0.020 with calipers when squeezed really hard with one hand. Same thing. Wash and dry.

Here's a large round count group at 100 with a 54 Hawken . 90gr 2f swiss. Wind was gusting so I was trying to hold for that. Without the wind, I can typically put them all in the black. My flintlock is a different story. As soon as I can see out of my right eye again I'll get out and shoot some more large count groups.

- Joined

- Oct 22, 2014

- Messages

- 14,682

I haven't tested it in a controlled enough manner myself to say for sure, but I did have a gun that cut patches due to rough/raised burrs on the edges of the lands from crap machining. After fixing that, the accuracy seemed better. Prior to fixing it I'd get occasional fliers way out of the rest of the group. Like something obviously wrong ... Not cherry picking and 3rd groups.

A few things:

Tight spot in breech after shooting- swiss has the potential to cause a worse fouling ring in the bottom, for whatever reason. I usually use schuetzen which is dirty as all hell in my gun (but does not make a hard ring) and tried swiss this year. After a couple shots, yes there's a crazy hard ring in the bottom and all other who've experienced this agree that when that hard ring forms your accuracy goes to crap... I think it probably changes pressure if it doesn't damage the patch. I have experienced the issue. I do not know how to prevent it other than swabbing it out.

The issue near the breech is pretty severe pitting- we used a bore scope and it is obvious. @longrangelead is going to see if he can lap it out.

As for Swiss, I have shot a bit with another MZ and have seen no real issue when not swabbing with it.

Shots being lower on clean bore - yes a clean bore produces lower MV and I guess lower pressure. I have noticed this with mine with certain loads. With a super tight combo in my two guns it seems to not make as much difference between clean/fouled bore. This is where having a tight enough patch/ball combo and a good lube helps. If it's tight enough, and the patch is moist enough, it will basically wipe the bore each time you load and give the same bore condition each time. I do this because taking the time to swab drives me nuts.

That is what I understand and what so far shows in previous shooting with other MZ’s. With this CVA is was just the pitting.

Patches- the prelubed are handy, but using a super tight weave and very strong material supposedly works best for accuracy. There are none of this quality that are prelubed that I know of. Using tighter weave that is stronger material means no gas blow by, which is supposedly beneficial to accuracy.

I’m going to test prelubed versus not heavily.

Idaholewis has shown it a couple times in his videos. He'll use precut patches that are thin, but he will double patch... Put a patch over the powder below the patched ball which protects the integrity of the patch on the ball. I haven't tested this myself because I went straight to loading the tightest load I could from the get go. However, I have seen accuracy degrade with damage patches or completely blown patches.

I will be trying the over powder wad/patch too.

Look into minute men patching. Tightest and toughest stuff I've found. Wash regular cycle, rinse twice, dry medium. Cut strips and then cut at the muzzle using spit for lube to make it easy. https://www.theminute-menpatches.com/ try the 0.018 and 0.020.

Already have some. Thank you.

Could also find some tight weave duck canvas that measures 0.018-0.020 with calipers when squeezed really hard with one hand. Same thing. Wash and dry.

I’m going to try a bunch of different patches, including leather and paper cartridges.

Here's a large round count group at 100 with a 54 Hawken . 90gr 2f swiss. Wind was gusting so I was trying to hold for that. Without the wind, I can typically put them all in the black. My flintlock is a different story. As soon as I can see out of my right eye again I'll get out and shoot some more large count groups. View attachment 995019

I don’t think keeping 10 round groups inside the black of a B8 bull at 100y will prove to be too much for PRB’s and a flintlock.

Appreciate the info man.

Grabbed a .45 flinter out of the safe yesterday. Haven't shot this one much and this is the first time putting it on paper. Here were the first 10 at 100yd off of a rest. Wind was 15mph gusting to 25mph. I held center on every shot and the horizontal stringing reflects it (8" horizontal vs 3" vertical spread). Not stoked with this group but it is a start.

Rifle has 36" douglas xx .45 barrel. Load was as follows:

.445" hand cast ball

.018" spit lubed pillow ticking patch cut at muzzle

70gr 3f goex (2024 production i.e. "New"/ Post Estes Energetics buyout)

Swiss 0b in the pan

No swabbing/cleaning

Going to be shooting this rifle some more in the near future to see what it will do with different loads in calmer conditions. Plan to change the sights soon as well as these are not comfortable for my eyes especially when dim/overcast.

Rifle has 36" douglas xx .45 barrel. Load was as follows:

.445" hand cast ball

.018" spit lubed pillow ticking patch cut at muzzle

70gr 3f goex (2024 production i.e. "New"/ Post Estes Energetics buyout)

Swiss 0b in the pan

No swabbing/cleaning

Going to be shooting this rifle some more in the near future to see what it will do with different loads in calmer conditions. Plan to change the sights soon as well as these are not comfortable for my eyes especially when dim/overcast.

HighUintas

WKR

- Joined

- Feb 2, 2020

- Messages

- 4,297

Awesome. Glad you found the problem.The issue near the breech is pretty severe pitting- we used a bore scope and it is obvious. @longrangelead is going to see if he can lap it out.

As for Swiss, I have shot a bit with another MZ and have seen no real issue when not swabbing with it.

That is what I understand and what so far shows in previous shooting with other MZ’s. With this CVA is was just the pitting.

I’m going to test prelubed versus not heavily.

I will be trying the over powder wad/patch too.

Already have some. Thank you.

I’m going to try a bunch of different patches, including leather and paper cartridges.

I don’t think keeping 10 round groups inside the black of a B8 bull at 100y will prove to be too much for PRB’s and a flintlock.

Appreciate the info man.

I'd like to get a 40 or 45 flintlock to try to conquer the flinch. The pan sound and flash and heavy recoil of my 58 makes me flinch quite badly. Best I've done is about 4" at 100 for 10 shots but my flinching makes that not repeatable.

HighUintas

WKR

- Joined

- Feb 2, 2020

- Messages

- 4,297

I'd be super happy with that with my flintlock. Dang flinching....Grabbed a .45 flinter out of the safe yesterday. Haven't shot this one much and this is the first time putting it on paper. Here were the first 10 at 100yd off of a rest. Wind was 15mph gusting to 25mph. I held center on every shot and the horizontal stringing reflects it (8" horizontal vs 3" vertical spread). Not stoked with this group but it is a start.

View attachment 995124

Rifle has 36" douglas xx .45 barrel. Load was as follows:

.445" hand cast ball

.018" spit lubed pillow ticking patch cut at muzzle

70gr 3f goex (2024 production i.e. "New"/ Post Estes Energetics buyout)

Swiss 0b in the pan

No swabbing/cleaning

Going to be shooting this rifle some more in the near future to see what it will do with different loads in calmer conditions. Plan to change the sights soon as well as these are not comfortable for my eyes especially when dim/overcast.

Glad to see theres another person here interested in showing what can be done with a flintlock on demand.

If you guys have any suggestions for getting rid of a flinch from the pan sound and flash, I'm all ears. I think it is more that than the recoil, but the recoil definitely doesn't help.

HighUintas

WKR

- Joined

- Feb 2, 2020

- Messages

- 4,297

This thread has me thinking I might need to get out and see what I can do shooting lefty since it could be months before I can shoot right again.

Similar threads

- Replies

- 30

- Views

- 2K

- Replies

- 34

- Views

- 2K

Latest posts

-

question for travelled hunters: where would you start if…

- Latest: mother_plucker

-

-

-

-

Featured Video

Latest Articles

- Banning Hunting Technology in Idaho?

- Best Gear of the year Rokslide staff edition 2025 Article

- Hunting Gear: Insights from Western Hunting Expo

- Black Diamond Alpine Start Insulated Hoody Review

- Tenacity Firearms with Andrew Whitney

- The Thrill of Moose Hunting with Henry Ferguson

- Final Rise Upland Hand Muff Review

- Kodiak Deer Hunt Round II

- Killing a Timber Giant

- Titanium Suppressor Shootout