The measure I showed is the Harrell's 90 Culver measure. I got it just under 10 years ago, it has gone up in price from $209.99 to $230 in that time. It's the cheapest measure Harrell's makes.

I measure powder three ways, and honestly, the Harrell's is my least used of the three due to my workflow, but I still can't imagine getting rid of it for reasons I'll elaborate on below.

First, let's look at repeatability. I chose four powders to test:

H1000 - Large stick extruded

Varget - medium stick extruded

8208 XBR - small stick extruded

Leverevolution - ball

Obviously there are plenty of powders in between, but this should show a decent representation of the performance.

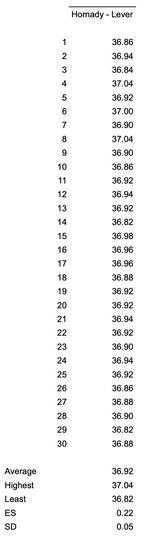

For this test I left the micrometer at one setting (54.75), dumped powder in, then threw 30 charges and weighed them on my FX120i (a lab scale that reads down to .02 grains and is well behaved for anyone unfamiliar). I didn't do any trick double tapping of the handle or body that I've read about anyone doing, I didn't discount throws that had some kernel binding, I didn't even throw a few to get it settled initially. Filled it up with powder and went for it. My results were:

View attachment 615255

I've done test's like this before, and am not surprised by these results. Even with H1000, I'm perfectly happy with this type of performance for:

Anything I do to 600 (I don't compete in the accuracy disciplines at 600).

Anything I do with a 223, my highest volume round (If I was trying to win a PRS match with one, I'd weigh, but I have yet to do that)

Club matches, especially with a powder like 8208 (or 4895 which throws pretty similar).

Three things really separate the Harrell's from say an RCBS thrower for me:

- It has a micrometer adjustment that clicks, is repeatable, and is linear

- It does seem to be more accurate/less particular about how you run it

- It clamps onto a flat edge instead of requiring a stand

For serious competition beyond 600 I weigh them, but with 8208 or 4895 it's pretty hard to tell the difference on target.

The Micrometer (at 54.75 here):

View attachment 615257

The micrometer is very repeatable, and most extruded powders are ~ 1.75 on the mic (or 7 clicks) per grain. So if I'm trying to throw 40.0 grains, I guess and throw one, lets say I get 38.5 grains. I'd add 10 clicks and throw again. After the third throw I should just be throwing a few to confirm I'm not a click off before I mass produce. And after I do that ONCE, I write down the mic number with my load data and can go back to it immediately, throw one or two to confirm, and I'm mass producing again.

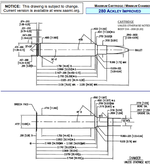

I mentioned I don't use the Harrel's a ton anymore for production (I'll get to that), but what I can't live without it for is load development. I can't shoot that close to my house, and I am pretty impatient with load development and want to have it done in one range trip. I do a little homework, finding a seating depth that's either .020"-.030" off the lands or whatever fits in the mag, then I find charge ranges I think are appropriate and quickly map the Harrell's mic to them, here's one from my notes I did from a 6.5 PRC from a while back:

View attachment 615258

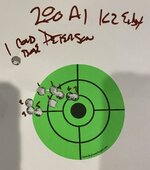

Then I get to the range, load and shoot (hopefully over the chrono) getting something like this:

View attachment 615259

Once I get home, I'll throw a handful at wherever I landed and write down the weight for reference as well.

For anyone loading in decent volume that isn't ONLY loading 1000yd level competition ammo, AND is loading single stage I'd definitely recommend considering something similar. The reason I don't use mine for production much is that I load everything on a progressive, and it's either using a powder funnel and the FX-120i w/ Autotrickler V2 as shown here:

View attachment 615262

I can do 200+ rounds an hour with prepped brass on that setup, pretty relaxed and weighing charges more or less to the kernel. Or...

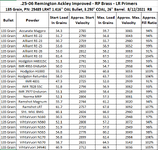

I set it up with the Hornady thrower with the case activated powder measure as shown here:

View attachment 615263

It's a bit less accurate and a bit more finicky to get dialed in. It does have a micrometer that works pretty well, and once I get it set it often stays there for 1,000+ rounds. And I only use it for 8208 or finer. It's pretty easy to exceed 300 rounds an hour with prepped brass and being relaxed about it.

I can stick the Harrell's in the powder funnel and use it that way; and I have in the past. However, my Autotrickler is so dialed at this point that for this workflow the Harrell's doesn't really save any time.