Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My mountain rifle is getting walnut…

- Thread starter Decker9

- Start date

Decker9

WKR

That is really beautiful work. Do you have a cheering layout in mind yet ?

I don’t no, once it’s finished up I’ll see how it feels and go from there. There’s a fellow in, Minnesota I believe, that I bs a lot on the Instagram, he’s a checking wizard, I think I’ll send the stock to him if I decide to checker it.

I’m getting better at checkering, slowly, but I’m afraid to dig into a nice stock just yet lol.

Decker9

WKR

The filets around the bottom metal, add a very nice look to a custom stock, but I find are hard to get perfect. A stock maker friend put me into a scraper for this, basically a knife that’s sharper on one side. It made things a little easier to keep the edges of the wood sharp im finding.

I do like the look of sharp lines, especially here, but functionally I don’t think it would have been good for the trigger finger though.

Out with the knife scraper

I do like the look of sharp lines, especially here, but functionally I don’t think it would have been good for the trigger finger though.

Out with the knife scraper

Decker9

WKR

You may notice, I got a new barrel for this build, lol. I found an old piece of pipe that fit into the barrel channel, I drilled a hole in it to attach it to the stock. It’s much nicer than having to worry about marking up the finish on my barrel / action in the vice. Not sure why it took me so long to figure this out. (Ignore the cluttered mess)

Decker9

WKR

As I get closer to finish, I find I mover around ALOT on the stock, giving time to think about every single move I make.

Back to the schnabel again and the forend transition.

Something I learnt here, don’t follow the barrel contour, instead, make a straight sharp top edge that runs from the front of the action to the forend, least for me personally, I prefer that look that when I got going on here.

Back to the schnabel again and the forend transition.

Something I learnt here, don’t follow the barrel contour, instead, make a straight sharp top edge that runs from the front of the action to the forend, least for me personally, I prefer that look that when I got going on here.

Been woodworking a long time, and this thread has me pumped up! Love the detailed photo documentation!

This is something I've wanted to do myself but I always seem to have more pressing projects.

This is something I've wanted to do myself but I always seem to have more pressing projects.

Jason Snyder

WKR

Wow! I love checking in on the updates on this thread.

HighUintas

WKR

- Joined

- Feb 2, 2020

- Messages

- 4,238

To darken and give a slightly reddish hue to your white walnut, you might look into using alkanet oil. This gentleman's oil is high quality and used by some of the best English style muzzleloader builders around

You might also look into using Laurel Mountain Forge Permalyn sealer as a sealer and stock finish. It is a modified poly varnish that can't be beat for weather resistance.

SB McWilliams Alkanet

We specialize in alkanet refinishing oil and varnish specifically designed for fine guns but they are used by furniture, guitar and violin craftsman as well

www.sbmcwilliams.com

You might also look into using Laurel Mountain Forge Permalyn sealer as a sealer and stock finish. It is a modified poly varnish that can't be beat for weather resistance.

Decker9

WKR

To darken and give a slightly reddish hue to your white walnut, you might look into using alkanet oil. This gentleman's oil is high quality and used by some of the best English style muzzleloader builders around

SB McWilliams Alkanet

We specialize in alkanet refinishing oil and varnish specifically designed for fine guns but they are used by furniture, guitar and violin craftsman as wellwww.sbmcwilliams.com

You might also look into using Laurel Mountain Forge Permalyn sealer as a sealer and stock finish. It is a modified poly varnish that can't be beat for weather resistance.

Iv been using Alkanet for a while now, my last build I used it for a little hue’ing, pretty cool stuff. The first finish I showed in this thread, was a mix of tru oil and boiled linseed mixed 50/50, then 25% mineral spirits soaked in Alkanet.

I dont think I want to go any more “on the wood” then what the tru oil gives, trying to be borderline, sealed but without on the wood type finish being to thick.

Jason Snyder

WKR

I used Permalyn as a finish and was pretty disappointed in itTo darken and give a slightly reddish hue to your white walnut, you might look into using alkanet oil. This gentleman's oil is high quality and used by some of the best English style muzzleloader builders around

SB McWilliams Alkanet

We specialize in alkanet refinishing oil and varnish specifically designed for fine guns but they are used by furniture, guitar and violin craftsman as wellwww.sbmcwilliams.com

You might also look into using Laurel Mountain Forge Permalyn sealer as a sealer and stock finish. It is a modified poly varnish that can't be beat for weather resistance.

There are some good on the wood finishes out there, with the obvious upside of more waterproofing... Murdoch's Uralkyd 500 floor finish by Sutherland Welles over a couple base layers of their hard sealer is my go to. I've used it to for high traffic tables, and to refinish bow handles. Might be worth a try.Iv been using Alkanet for a while now, my last build I used it for a little hue’ing, pretty cool stuff. The first finish I showed in this thread, was a mix of tru oil and boiled linseed mixed 50/50, then 25% mineral spirits soaked in Alkanet.

I dont think I want to go any more “on the wood” then what the tru oil gives, trying to be borderline, sealed but without on the wood type finish being to thick.

This was their satin finish, and probably 6 coats, just ignore that boat in the background.

HighUintas

WKR

- Joined

- Feb 2, 2020

- Messages

- 4,238

I used Permalyn as a finish and was pretty disappointed in it

Yes, Permalyn takes a bit of figuring out to get it to look the way you want. All finishes vary in their difficulty of use and that one seems to cause people more grief than others. I redid the finish on my rifle after using it the first time because it came out too much on the wood and more glossy than I like. It is also generally important that the Sealer is used for both sealing and finishing rather than using the Finish, because the Finish is so much thicker and harder to get the look most people want.

With the correct application, it is marvelous looking and a trained eye can't tell the difference between that and a 200 year old linseed varnish!

I found what works best for me, is after the stock has been sealed I use the Sealer and hand rub it in in small sections in VERY sparing amounts to the point it gets very tacky and warm. This produces a nice soft sheen that replicates the hand rubbed look without being glossy and on the wood.

This is all of course my preference, and I prefer to use it because some tests shown by longrifle builders show it to have superior weather resistance compared to other oils, oil varnishes, and even other modern polys

Kimmo H

FNG

- Joined

- Jan 3, 2023

- Messages

- 60

I don't do much stock work, but from my limited experience Tru Oil is a very good finish of high quality wood when done properly in very thin layers over a long period of time.

I had a F3 Blaser shotgun with gorgeous wood on it, and I refinished it with a Tru oil treatment. I went for a shiny, glossy finish look and it turned out beautiful. Lasted very nicely too in bad weather and hard use. It took me a lot of time to do initially with all the layers and sanding between them, but after that it was easy and quick to touch up once a year after the initial finish to keep it sealed and looking clean.

I personally like the subtle tint of tru oil, as it makes the grain pop more and gives the wood a perception of depth that some other finishes don't.

I had a F3 Blaser shotgun with gorgeous wood on it, and I refinished it with a Tru oil treatment. I went for a shiny, glossy finish look and it turned out beautiful. Lasted very nicely too in bad weather and hard use. It took me a lot of time to do initially with all the layers and sanding between them, but after that it was easy and quick to touch up once a year after the initial finish to keep it sealed and looking clean.

I personally like the subtle tint of tru oil, as it makes the grain pop more and gives the wood a perception of depth that some other finishes don't.

Dos Perros

WKR

@Decker9 has removed all the wood that was not David.

Decker9

WKR

I appreciate the recommendations on finishes fellas, finishing is a trade in itself im finding. My favourite so far is a tung oil finish, done properly with wet sanding to fill pores, and bare hand rubbing until it burns a layer of skin off ( exaggerating, kinda)

Tbh I always put tru oil in the gimmick category, but after bs’ing with a old time stock maker who’s used it all, tru oil sounds like a great product, either by itself or as a base and modified how one likes his finish.

Another great finisher, for sealing, saturates the whole stock in spar urethane, lets it dry a week or two then sands it down to wood, leaving the pores filled. I can’t help but think though that a guy might get a glitter looking finish maybe, though I can see how that system would seal and harden the wood quite well.

I’m not sure there’s enough time in a lifetime to try them all lol.

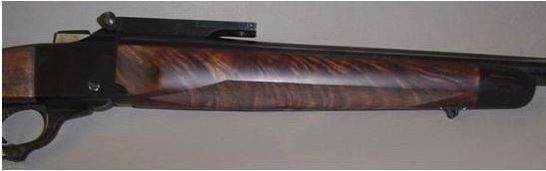

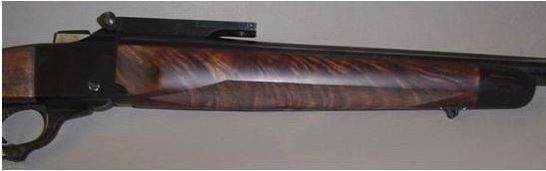

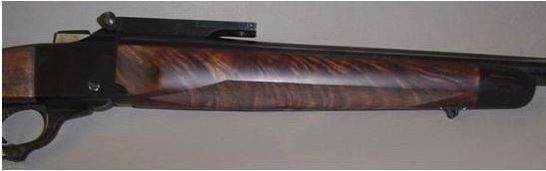

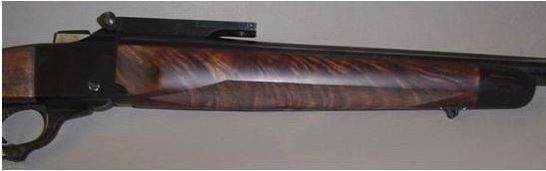

Double checking my comb is correct.

Catching those carbons

(5 1/5 pounds roughly, still needs a pad and finish)

(5 1/5 pounds roughly, still needs a pad and finish)

A bit of shaping and sharpening the flow lines, jumping between scrapers files and sandpaper. (may not be in total order)

Tbh I always put tru oil in the gimmick category, but after bs’ing with a old time stock maker who’s used it all, tru oil sounds like a great product, either by itself or as a base and modified how one likes his finish.

Another great finisher, for sealing, saturates the whole stock in spar urethane, lets it dry a week or two then sands it down to wood, leaving the pores filled. I can’t help but think though that a guy might get a glitter looking finish maybe, though I can see how that system would seal and harden the wood quite well.

I’m not sure there’s enough time in a lifetime to try them all lol.

Double checking my comb is correct.

Catching those carbons

A bit of shaping and sharpening the flow lines, jumping between scrapers files and sandpaper. (may not be in total order)

Have you heard of a wood finish , oil finish, that you slather on wet, then rub it in with a dowel rod? Not sure the whole process but it

drives the oil in deep and hardens The wood surface.?not sure the product used or how many coats sanded in between .

drives the oil in deep and hardens The wood surface.?not sure the product used or how many coats sanded in between .

TaperPin

WKR

- Joined

- Jul 12, 2023

- Messages

- 6,317

Looking good!I appreciate the recommendations on finishes fellas, finishing is a trade in itself im finding. My favourite so far is a tung oil finish, done properly with wet sanding to fill pores, and bare hand rubbing until it burns a layer of skin off ( exaggerating, kinda)

Tbh I always put tru oil in the gimmick category, but after bs’ing with a old time stock maker who’s used it all, tru oil sounds like a great product, either by itself or as a base and modified how one likes his finish.

Another great finisher, for sealing, saturates the whole stock in spar urethane, lets it dry a week or two then sands it down to wood, leaving the pores filled. I can’t help but think though that a guy might get a glitter looking finish maybe, though I can see how that system would seal and harden the wood quite well.

I’m not sure there’s enough time in a lifetime to try them all lol.

Double checking my comb is correct. View attachment 656087

Catching those carbons(5 1/5 pounds roughly, still needs a pad and finish)

View attachment 656086

A bit of shaping and sharpening the flow lines, jumping between scrapers files and sandpaper. (may not be in total order)

View attachment 656083View attachment 656084

View attachment 656080View attachment 656081View attachment 656082

View attachment 656085

There are a lot of finishes that aren’t quite as described on the label, especially oil finishes. I have clients that ask for furniture or countertops with certain finishes and it takes a while to explain the chemistry. Basically, nobody would buy 100% Tung oil if it were actually all Tung oil since it wouldn’t dry to a hard surface quickly - the small amount of urethane, or whatever the hardener is, still keeps the look of a thin oil, but builds much quicker. You seem to have good judgement about it all - there’s no rocket science to a good finish, just pick one and stick with it.

HighUintas

WKR

- Joined

- Feb 2, 2020

- Messages

- 4,238

Polymerized tung oil will harden and is awesomely weather resistant. It can be 100% tung.

Decker9

WKR

Have you heard of a wood finish , oil finish, that you slather on wet, then rub it in with a dowel rod? Not sure the whole process but it

drives the oil in deep and hardens The wood surface.?not sure the product used or how many coats sanded in between .

That’s a new one to me, Iv heard of by hand or with a lint free cloth, or wet sanding, but never heard of using a wooden dowel.

Similar threads

- Replies

- 69

- Views

- 4K

- Replies

- 90

- Views

- 9K

Featured Video

Latest Articles

- Kodiak Deer Hunt Round II

- Killing a Timber Giant

- Titanium Suppressor Shootout

- Best Gear of 2025

- Swarovski AT Balance Review

- YETI Outdoor Kitchen Expansion

- The Art of Shed Hunting

- TT#72 Conquering the Super 10: Mike Kentner’s Hunting Journey

- Spring Black Bears with Joe Kondelis

- TT#71 Trail Goods Company – Partnering with Hunters for Epic Adventures