Lawnboi

WKR

I already have the amp that’s the reason for the amp mate.Not to hijack a thread, but just get an Ugly annealer. Way less than an Amp setup, and pretty quick. It’s what I use.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I already have the amp that’s the reason for the amp mate.Not to hijack a thread, but just get an Ugly annealer. Way less than an Amp setup, and pretty quick. It’s what I use.

Would you mind explaining the difference between the SAC mandrel/de capper and a normal die expander? If I understand it correctly the mandrel works in place of an expander but just expands the case mouth less after the bushing sizes it? (Less brass movement?) I have thought about just going to 6 and 22CM or 6 and 22GT and buying a SAC die setup.Iv also gone to mainly carbide mandrels due to the galling issues.

Little more expensive.

Same with sizing dies, SAC with the carbide mandrel/decapper keeps things nice and smooth.

Is the moly you use a liquid? Might need to try it. Graphite didn’t do it for me. I wipe imperial on the rim right now but I’m all for something that’s less gummy.

He's discussed it a lot. Pay attention to Tom when he shows up in the threads. He shoots, tests and wins a lot.Alex Wheeler annealing write up

@huntnful , do you have a link to that Alex Wheeler annealing write up? I'd like to read it.

I have tried to simplify my process as much as possible in the last year as well.

Anneal, sometimes

Brush inside neck

Put cases in Ziploc with Lee lube and shake around

Size w standard FL die

Wipe off lube

Trim if needed

Prime and load

I found absolutely no difference in accuracy or speed consistency with this process vs nitpicking everything, annealing every time, etc

Would you mind explaining the difference between the SAC mandrel/de capper and a normal die expander? If I understand it correctly the mandrel works in place of an expander but just expands the case mouth less after the bushing sizes it? (Less brass movement?) I have thought about just going to 6 and 22CM or 6 and 22GT and buying a SAC die setup.

'preciate it!!The mandrel goes through the neck as it exits the bushing. The biggest plus to a standard die on this is that it’s adjustable. So both the sizing and mandrel operation do as little as they need to. The expander is carbide as well so it leaves a nice smooth neck. But yes it expands on the way down like a typical die with a few differences.

The beauty of the sac die is in it all together. Neck shoulder bushing seems to keep doughnuts away, and dosnt leave an unsized portion for brass to build up. They also size farther down the case than most other dies Iv used. I could not measure a difference between the expanding decapper in place and a separate mandrel step, so it all gets done at once. The die is very adjustable and does as good or better of a job than anything. I seat on an arbor press so with this I’m only pulling the lever of the press one time per case.

If you’re not a believer in using a mandrel, they come with a decapping pin. Personally I just use a mandrel, my brass necks always end up dinged up and it just smooths them out.

At one point I was loading 22, 6 and 6.5 off the same die body with only changing bushings, mandrels and shell holders (Redding comp)

They are nice dies, and the time saver is worth the steep price for me. SAC has also been great to work with from a customer service standpoint when I have had questions or gotten the wrong item.

Smooth out the oxidized annealed surface inside the necks. I tested it early in this thread as well. Pretty big difference in seating pressures and ES by just brushing the necks on virgin brass as opposed to not brushing them.I understand brushing the necks of fired brass but what does brushing virgin brass do?

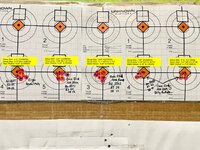

This is interesting! I know others have said the same thing, but then others have said otherwise. Goes back to things being simple! Why I’m on this topic, I have a quick question for you. Doesn’t directly relate to the topic at hand, but not too far off. I don’t mean to derail anything. Question: In your experience, when you shoot a powder ladder with a charge spread of say 2-3 grains, and the ladder doesn’t group well on paper, do you pursue that bullet or load at all, or immediately move on to something else? I’d love to shoot 73 or 75 ELD-Ms out of my Tikka 223 for practice, but powder ladders to find where I get to pressure haven’t grouped well. In fact, none of the 3 different ELD-Ms have shot well. So far, just the 77TMK & Hornady 75 BTHP have shot good. Do I scrap trying to dev any of the ELDs further?What I see from this small test is that .040 difference in seating depth made no significant change to group size.

The people that know seating depth matters, have far better equipment and shooting skill than I do in order prove it. If someone who consistently shoots the smallest groups in the world says it makes a difference, it does. But they are literally going from a .3 average to a .2 average. I would just never be able to tell that difference with my equipment. And I always test seating depth… to no avail lol.This is interesting! I know others have said the same thing, but then others have said otherwise. Goes back to things being simple! Why I’m on this topic, I have a quick question for you. Doesn’t directly relate to the topic at hand, but not too far off. I don’t mean to derail anything. Question: In your experience, when you shoot a powder ladder with a charge spread of say 2-3 grains, and the ladder doesn’t group well on paper, do you pursue that bullet or load at all, or immediately move on to something else? I’d love to shoot 73 or 75 ELD-Ms out of my Tikka 223 for practice, but powder ladders to find where I get to pressure haven’t grouped well. In fact, none of the 3 different ELD-Ms have shot well. So far, just the 77TMK & Hornady 75 BTHP have shot good. Do I scrap trying to dev any of the ELDs further?

Thanks! That’s basically what I was told by someone else, and I just wanted to verify that from another loader.I intentionally shoot a powder ladder at the same POA, and if it doesn’t group half ass,

It’s not even worth messing with IMO. Even across 2-3 grains it should shoot just fine. Maybe a slight vertical spread if anything.

If it’s a scattered looking group that’s outside your intended maximum group size, save yourself the headache and move on

No problem!Thanks! That’s basically what I was told by someone else, and I just wanted to verify that from another loader.

Really appreciate the testing on the 22 Creed. Very interesting to see all the different techniques used and their effect (or not) on groups.

Yeah I don’t think the ELDM line can compare to Berger as far as pure precision at longer ranges day in and day out. I just like how they well they kill, they’re cheap, and they still normally shoot pretty damn good.Seating depth will show itself more at distance. More on some barrels then others and more with certain bullets then others. The eldm line seems more forgiving if you will for seating. But i also think they can never shoot as small as a tips would or bergers

I have 40.5gr and 40gr. loaded up to test. Just curious to compare case heads and possibly group sizes, but I’m sure they’ll all shoot well.Yea cleaning primer pockets is a waste of time, you can knock that one off the list.

That gun is shooting well. I could have predicted a velocity increase and being on the ragged edge of pressure. Would be interesting to see you continue at that but I do get toning it down.

Careful with that. You’re up there in pressure according to velocity. Wrecking some brass will be okay but I’d hate to etch my firing pin on a load that honestly is probably not safe with any moisture involved.Yeah I don’t think the ELDM line can compare to Berger as far as pure precision at longer ranges day in and day out. I just like how they well they kill, they’re cheap, and they still normally shoot pretty damn good.

I have 40.5gr and 40gr. loaded up to test. Just curious to compare case heads and possibly group sizes, but I’m sure they’ll all shoot well.

@Dioni A gave me a good test to try as well. Wetting the cases and see how they pressure up in the chamber to mimicking a moist rainy hunt. I have 40, 41 & 42gr. loaded up for that test as well.