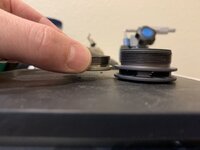

I don't understand why SiCo hasn't updated the Scythe Ti specs and manual with restrictions after doing multiple repairs on failed welds. Maybe

these anecdotal seperations are just a blip on the radar for them compared to sales volume.

They say the Scythe Ti is for bolt and semi, not rated for full auto. They say no barrel length restrictions.

But why don't they do what other suppressor manufacturers have done and publish a firing schedule (XX shots before allowing the suppressor to cool) or a temperature limit (keep under 800 degrees) to help their customers avoid weakening their cans and having a weld let go when they use it on a short barreled magnum?

My guess is that the amount of shooting they would have to do to replicate these failures and identify reasonable limitations is percieved as cost and time prohibitive. But it's exactly what I'd want a suppressor manufacturer to invest in up front and not use their customers as product testers.

Another possibility is that they have identified something internally with their orbital welding process, or their training and process adherance, or weld inspection (penetrant or x-ray) or something else that they have changed in the background that they think has resolved this issue without making any statements or recalls.

shotshow.org