Get the 3 stone standard sharpening system with Coarse, Medium, and Fine stones. Buy an Ultra Fine stone and a Medium Diamond stone also.

View attachment 808217

Get the Super C Clamp as it is a must have. Makes it faster, safer, and much easier sharpening knives.

View attachment 808218

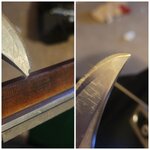

Last thing to get is replace the standard/Phillips head screw in the blade clamp with a Hex head screw and get an Allen wrench to fit the screw as shown below. Get the same length & diameter obviously as the screw that comes in the kit but just with the Hex head on it. Get an Allen wrench to fit the screw and put that into your sharpening kit for snugging the blade clamp. Get a couple of the screws, nice to have an extra. Then get a couple Hex head screws but just the next length longer. Sometimes on thicker blades the longer screws come in handy so you can manipulate the blade clamp to get the most bite/holding power on the knife blade. You'll figure it out once you get the system. The Allen wrench makes it a lot simpler and easier to use the system and the wrench fits easily in the kit when not in use. Way more so than a stubby screwdriver. Get all of this and start sharpening.

View attachment 808222

A first time knife that I have never sharpened before and so it doesn't have perfect edges on it takes me about 25-35 minutes on average to get to an ultra razor sharp edge. Knives that I have sharpened previously and take care of and aren't in bad shape take at most about 10 minutes to 15 minutes to get to where the edge is perfect in my mind at least.