BRTreedogs

WKR

Digital calipers, with the cbto tool bushing.What are you measuring with?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Digital calipers, with the cbto tool bushing.What are you measuring with?

I do the same. Do you know the accuracy of your caliper? My Mitutoyo 6" is +/- .001", even though all measurements read the same the batch could be off .002".Digital calipers, with the cbto tool bushing.

Sure sure.I do the same. Do you know the accuracy of your caliper? My Mitutoyo 6" is +/- .001", even though all measurements read the same the batch could be off .002".

Yes, stacking. I use an old Rock Chucker, what I've found to make the biggest difference is how I cycle the handle. I suspect that's true regardless of the press.Sure sure.

But that further proves my point.

If the press and the calipers both could have errors, well that could be a double error.

My Mitutoyo is very accurate. I bump the shoulder .002 as most of us do. If we are off by .002 then we are all shooting ourselves in the foot aren't we?I do the same. Do you know the accuracy of your caliper? My Mitutoyo 6" is +/- .001", even though all measurements read the same the batch could be off .002".

Depends if it didn't bump at all for some reason they may not chamber.My Mitutoyo is very accurate. I bump the shoulder .002 as most of us do. If we are off by .002 then we are all shooting ourselves in the foot aren't we?

View attachment 503981

I measured the differences between my spare turrets and it is +/- a fly's butt.Sure sure.

But that further proves my point.

If the press and the calipers both could have errors, well that could be a double error.

When you get started, check a dummy round for chambering just in case the measurement is off. I wouldn't worry about spring-back because it measures what it is. My chamber head spaces at .275 and it doesn't matter what brand of brass, all will fire form to .275. If you want some insurance, then just bump it back .004 and give it a try. You will be working the brass a little more, but if you anneal it shouldn't matter.Depends if it didn't bump at all for some reason they may not chamber.

I loaded 150 rounds of brass fires in a different rifle and they won't chamber.

If you get a quality seating die, you can replace the seating stem for the shape of your bullet. I have three different seating stems in .308 and the one that fits the nose of the bullet correctly goes in the die.The only way I can see there would be a difference then is if your seating stem is pressing on the tips rather then the ogive.

The ogive should be very consistent.

That .002" I mentioned would be .001 under to .001" over. I don't know a single hunting rifle that would shoot different with that range.My Mitutoyo is very accurate. I bump the shoulder .002 as most of us do. If we are off by .002 then we are all shooting ourselves in the foot aren't we?

I missed this part...If your dies are properly setup to bump .002 for your chamber, you will need to resize the brass fired in another chamber with your dies. You should have measured the headspace on the fired brass before you resized it. Then you would have known if the headspace was greater than your chamber. If the brass fired in another rifle head-spaces >.001 less than your chamber, then it is all moot.I loaded 150 rounds of brass fires in a different rifle and they won't chamber.

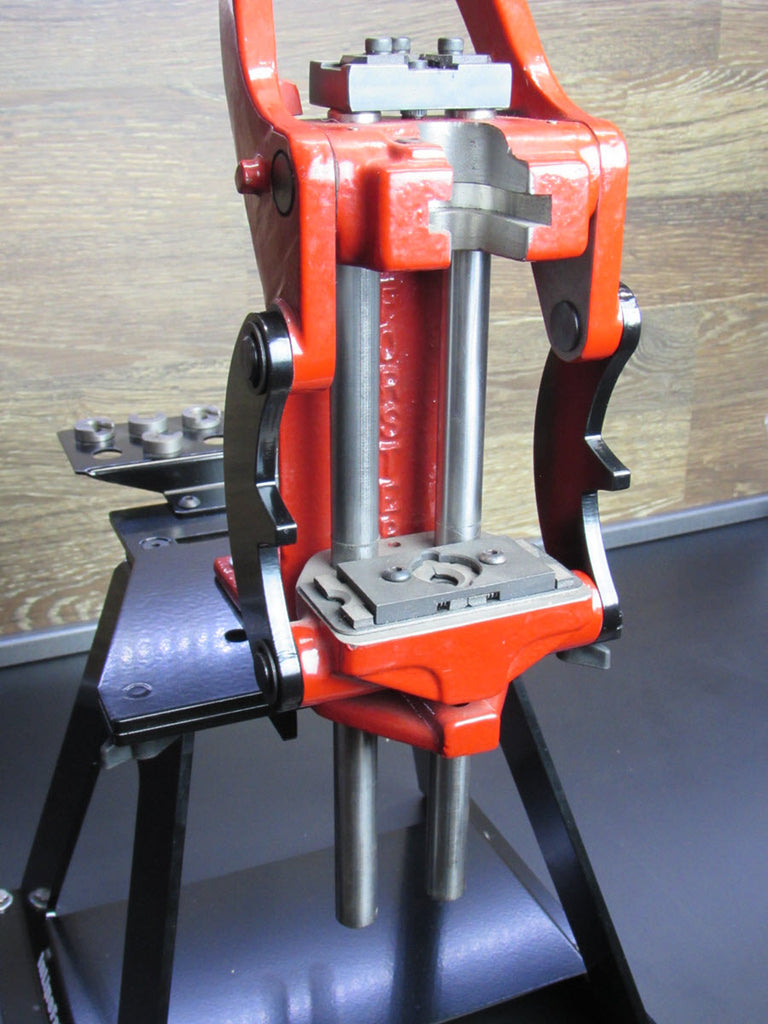

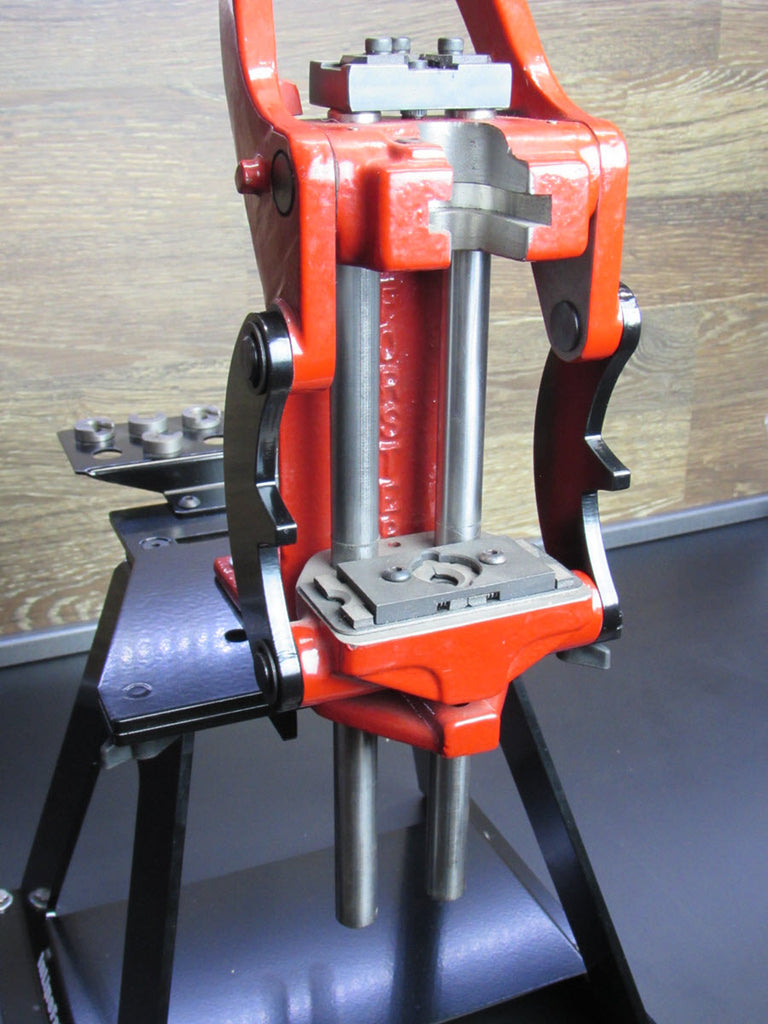

I don't have any experience with a T-7, but can say I really like my Co-Ax. This was actually my first press ever, so don't have comparisons vs anything else either. However, my brother reloads and a lot of my decisions have been based on his feedback and experience using both progressive and single-stage presses.Ive ran an RCBS Rock chucked for 25 years. Over the last few years, I’ve invested an embarrassing amount time researching and debating between the Forster Co-Ax and Redding T-7. I like the set it and forget advantage of the T-7, as I load for several calibers anyhow. But the Forster is somewhat the same once dies are set…

Does anyone have any specific negative experience with either press?

Great information, thanks so much!I don't have any experience with a T-7, but can say I really like my Co-Ax. This was actually my first press ever, so don't have comparisons vs anything else either. However, my brother reloads and a lot of my decisions have been based on his feedback and experience using both progressive and single-stage presses.

Looking back, I imagine I spent a lot more money on my setup than I could have. The accessories and dedicated die rings add up to the investment. However, I consider these time-saver items which are huge to me. I often find myself with only a few hours on a weekend to load something due to life (kids activities, chores, etc). If I was at a later stage in my life, I imagine I would have a lot more time to sit in front of my press.

I suggest using their aluminum die rings since other brands are steel. I would rather have a die ring wear, than the slots in my press. As mentioned, these get expensive so suggest buying in bulk packs.

I also dislike the priming feature. I used it for the first year and it does work well. However, I found I'm much more efficient using a hand-priming tool. I have an RCBS hand-primer which I estimate requires 30-50% the time that using the Co-Ax does.

Last 'dislikes' of the press, looking back, is hand accessibility and lighting. I used the press for about a year and then added a lighting kit and some redesigned linkage bars. My eyesight is terrible and the LED lights help so much. Links to each of these items are below.

Forster Co-Ax Increased Access Side links Linkages CoAx - Inline Fabrication

For reloaders that need a little more room when loading and unloading the shellholder. These have been very well received/reviewed...inlinefabrication.com

Hope this helps with your decision. If you can afford it, I don't think you'll have any regrets.

Best of luck

Man you're awesome.And I thought my wife was OCD. Some of you guys take the cake by a LOOOOOOONG shot. lol

Filthy Rockchucker guy here. And if I didn't get a screaming deal, I would be using a LEE. Blasphemy!

Meh, I got walls full of animals....so whatever.