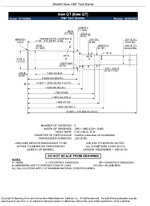

I hate to introduce anything factual into a lively discussion, but if anyone has ever wondered why some rifles carbon up and some don’t, it’s at least partially explained by the chamber tolerances. Factory rifles are SAAMI spec and that spec has a tolerance, which is easy to look up on SAAMI.org. I see Hornady has submitted the 6 GT, so that new rifle of yours has a chamber that looks like the 1st drawing. Notice the throat diameter is .2436” - that’s leaving .0003” gap around the bullet. Thin aluminum foil is .001” ish, so it’s 1/3 the thickness of thin foil. However, the tolerance listed down in the fine print is +.002”, so it can be as large as 1-1/3 pieces of foil all around the bullet. Where your gun falls only careful measurement can tell, but a 2 yr old can look at two gaps he’s trying to squeeze through and know one that’s 4x as wide has a lot more wiggle room.

Now look at the test barrel tolerance. The tolerance isn’t +.002”, but only +.0005”. Again, no mathematician, but Toddler-Taper can tell you something with 4x smaller gap is harder to get through. The 5 year olds here at Taper World Headquarters can even verbalize the difference in terms of Lincoln Logs, or Legos, but you get the idea.

If I was a Flat Earther, I mean anti cleaner, I’d point out the Hornady data applies only to tight chambered test barrels or minimum chambered custom barrels and not average hot-dog-down-a-hallway factory barrels.

View attachment 810568View attachment 810567