After seeing a couple of the diy carbon stock builds I decided to give this a shot. Thanks to roksliders @RepeatPete and @hpmr for the insperation and answering my questions.

Started with 3 layers of xps foam from home depot. It's labels as 1/2" but it's slightly thicker.

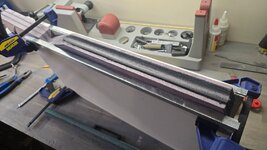

Laminated 3 layers together with 2 layers of carbon sandwiched between for a total of 4 layers of carbon. (cheap stuff from Amazon) trying to keep this build as cheap as possible.

Trying to take lots of photos in case anyone wants to give it a try as well.

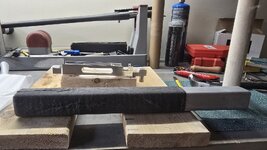

Tools are pretty basic so far.

Sand paper of various grit from 60-320

1-1/8 dowel for barrel channel with 60 grit paper glued to it and a drawer pull as a handle.

Jewellers wire coping saw

Two pieces of mdf with 1/2" angle aluminum used as a guide or fence for cutting with the jewelers saw(slow but quite precise with little to no tear out from the saw)

Assorted files and rasps

Some quick clamps and c clamps.

Waiting for the bedding block from stockys to arrive. Will be assaulting it with a grinder/Dremel because I'm left handed.

Will probably start carbon skinning the grip/action area to add rigidity as I started inletting for the bottom metal and I'm absolutely trash with a Dremel, as in I don't even want to post a photo of it haha.

Current weight: 147 grams / 5.18oz

Edited to add weight

Started with 3 layers of xps foam from home depot. It's labels as 1/2" but it's slightly thicker.

Laminated 3 layers together with 2 layers of carbon sandwiched between for a total of 4 layers of carbon. (cheap stuff from Amazon) trying to keep this build as cheap as possible.

Trying to take lots of photos in case anyone wants to give it a try as well.

Tools are pretty basic so far.

Sand paper of various grit from 60-320

1-1/8 dowel for barrel channel with 60 grit paper glued to it and a drawer pull as a handle.

Jewellers wire coping saw

Two pieces of mdf with 1/2" angle aluminum used as a guide or fence for cutting with the jewelers saw(slow but quite precise with little to no tear out from the saw)

Assorted files and rasps

Some quick clamps and c clamps.

Waiting for the bedding block from stockys to arrive. Will be assaulting it with a grinder/Dremel because I'm left handed.

Will probably start carbon skinning the grip/action area to add rigidity as I started inletting for the bottom metal and I'm absolutely trash with a Dremel, as in I don't even want to post a photo of it haha.

Current weight: 147 grams / 5.18oz

Edited to add weight

Attachments

-

20250412_103506.jpg181.1 KB · Views: 152

20250412_103506.jpg181.1 KB · Views: 152 -

20250412_103515.jpg185.5 KB · Views: 147

20250412_103515.jpg185.5 KB · Views: 147 -

20250412_152628.jpg160 KB · Views: 145

20250412_152628.jpg160 KB · Views: 145 -

20250412_114050.jpg184.2 KB · Views: 153

20250412_114050.jpg184.2 KB · Views: 153 -

20250408_200103.jpg183.6 KB · Views: 188

20250408_200103.jpg183.6 KB · Views: 188 -

20250412_152403.jpg156.1 KB · Views: 192

20250412_152403.jpg156.1 KB · Views: 192 -

20250408_185040.jpg136.1 KB · Views: 197

20250408_185040.jpg136.1 KB · Views: 197 -

20250408_184808.jpg194.7 KB · Views: 166

20250408_184808.jpg194.7 KB · Views: 166