Main purposes right now:

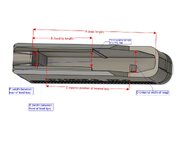

1) Do these the model files fit well on other's guns and in field use. That provides a template to play with more.

2) How does this material hold up so color options are on the table for fun.

Color options is really the only point in seeing if the the petg-gf seems to hold up well (or at least okay). Its something that isn't super expensive, prints decently (with hardened nozzle and extruder), and shouldn't soften in a hot vehicle or similar and warp (a risk with PLA). If that doesn't hold up then its just "boring" black and muted colors typically infused with carbon. Glass is clear so it allows brighter colors. Maybe someone else knows of a stiff, temp resistant, wear resistant filament material in colors as an alternative?

black and muted colors typically infused with carbon. Glass is clear so it allows brighter colors. Maybe someone else knows of a stiff, temp resistant, wear resistant filament material in colors as an alternative?

This thread hasn't attracted others with printers much yet. I'm getting the impression folks are going to want me to print them out mag bodies if this color option pans out, which I can, but lets also not loose the sight of group creativity and development I'm trying to inspire.

They have a green for the rokslider die hards too! (This is just one manufacturer, I'm sure there are more options out there but fun enough in my opinion).

1) Do these the model files fit well on other's guns and in field use. That provides a template to play with more.

2) How does this material hold up so color options are on the table for fun.

Color options is really the only point in seeing if the the petg-gf seems to hold up well (or at least okay). Its something that isn't super expensive, prints decently (with hardened nozzle and extruder), and shouldn't soften in a hot vehicle or similar and warp (a risk with PLA). If that doesn't hold up then its just "boring"

This thread hasn't attracted others with printers much yet. I'm getting the impression folks are going to want me to print them out mag bodies if this color option pans out, which I can, but lets also not loose the sight of group creativity and development I'm trying to inspire.

They have a green for the rokslider die hards too! (This is just one manufacturer, I'm sure there are more options out there but fun enough in my opinion).