Kenny Hart

Lil-Rokslider

- Joined

- Feb 5, 2023

- Messages

- 270

Great question! Simply because it's 3D printed, which comes with its own complications.Why not integrate the cheek riser into the spacer? It could be held on with it being built onto the spacer at the rear, with 1 vertical screw and a plug up front, just like the factory CTR riser…all one piece.

That additional height would add A LOT of time to the print (more time for something to go wrong/tie up the machine for customer prints), would be a tall unsupported piece that could be subject to warping, and use more material.

I could mitigate some of those downsides by printing the part lying down, but I wanted the build layers and internal lattice structure to be strongest in direction of the recoil, as well as have a perfectly flat interface with the stock. It would look worse from a visual aspect to have the build lines running horizontally.

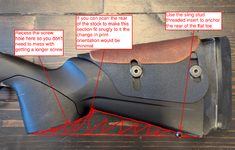

It also would have forced me to be more creative with how I would install a threaded insert for the recoil pad. I certainly could've installed them on the side adjacent to the recoil pad, but for pullout resistance I wanted the additional support of the thickness of the spacer to give far more "pull-through" resistance versus just having an insert 3/8 of an inch deep whose pullout resistance rests solely on the small amount of plastic surrounding it. Lets me really crank down the pad with those screws.

The separate cheek riser is a much easier solution, all it requires is an internal support for the clamp screw that you could simply cut a short section of PVC for, as well as the spacer shelf that I have the rear of it sitting on.