I have found the same lack of surface adhesion between resin & synthetic (plastic) stock material. The rough sanding does give it some ‘tooth’ to bind to, so the rougher / deeper the serrations, the better. I’ve even gone with dremel wheel cuts that leave triangular angled walls to mechanically lock the resin in place.

Another thought on the grip area- to find the right shape, I start with an ideal trigger finger engagement with the pad of the finger split on the trigger blade and then bend at the second index knuckle to a right angle. Where the remainder of the hand comes to rest on the grip area is where the filler goes. This is where the beauty of an epoxy dough comes in. I simply glove up and squash the dough (or resin/micro balloon mixture) into place. You can get as good a fit as you want and then later sand away what is not needed taking into account whatever thickness of CF will be added later.

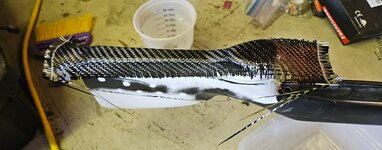

On my latest stock build, I actually left the grip area unsealed so I can re-shape the grip by simply sanding away the old material and re-applying another fitted layer. Looks rough as a cob, but functions really well. This is an old pic of initially trying spray on bed liner. Worked well for a few months, but eventually peeled. Once I settle on a shape profile, I will either coat it with something or skin it with CF.

As to applying your outer layer of CF, will you be vacuum bagging or stretch wrapping it?

Doing the outer shell in sections really simplifies the process- divide and conquer rather than an all-in-one shot approach makes it muuuuch easier in the end. The forearm section and stock section probably won’t need a lot of reinforcement, but the grip area probably will. Recommend the grip area last so you can make it as stiff as needed. And multiple layers with sanding and filling in between will give much better results. Since you will be potentially adding rigid layers of CF, you can sand away significant portions of the underlying host stock if you like.

BTW- what part of AK? I was in Kodiak back in the 90’s for a few years and these type gun projects are sanity savers in the dark days of winter.