If I had the time. I've had a few ask but have to find time to do it. Have complete building items as well as wiring schematic. Cost me about $80 in materials.That's badass! When will you start taking orders??

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do in the reloading room today?

- Thread starter sierracharlie338

- Start date

letrbuck

WKR

I'd totally be in for a parts list and schematic. Nicely done sir!If I had the time. I've had a few ask but have to find time to do it. Have complete building items as well as wiring schematic. Cost me about $80 in materials.

WestTN2288

Lil-Rokslider

- Joined

- Jun 26, 2022

- Messages

- 191

If I had the time. I've had a few ask but have to find time to do it. Have complete building items as well as wiring schematic. Cost me about $80 in materials.

Yeah, I’d be on the list for parts too. Surely we can crowd fund you a bottle of whiskey for your efforts?

I'd totally be in for a parts list and schematic. Nicely done sir!

DispenserYeah, I’d be on the list for parts too. Surely we can crowd fund you a bottle of whiskey for your efforts?

This is a thread i had started. In the thread is a list of all the items as well as an attached wiring schematic.

Slick8

WKR

- Joined

- May 8, 2019

- Messages

- 482

I just walked by mine and sighed today....

On a bright note, I'm making 50 pounds of snack sticks and 50 pounds of link this weekend.

On a bright note, I'm making 50 pounds of snack sticks and 50 pounds of link this weekend.

Put my new shell holder in my press and got some primer on the bench. Slowly getting ready.

Also looked at pictures of an upcoming gun auction at guns I won't be able to buy but at least I can drool over the pictures of a a couple 1873s in 44-40 and 38-40 and some model 94s in 25-35. One day.... One day...

Also looked at pictures of an upcoming gun auction at guns I won't be able to buy but at least I can drool over the pictures of a a couple 1873s in 44-40 and 38-40 and some model 94s in 25-35. One day.... One day...

For many years I've been reloading under marginal conditions. Just a closed in room in an old equipment barn. I usually load most of my stuff in the winter when it's cold and rainy and I can't work outside. I run a sawmill business.

This year I built a new room under the same roof, but it's insulated to the max, vapor barrier, fully sealed with HVAC. I just started today framing the first workbench and it'll have a 2 inch slab top 30 in wide and 12 ft 6 long. Hopefully it'll be heavy enough that seating bullets doesn't screw up my electronic powder measure.

Now, I will be able to reload in the summertime. We have a lot of days where the heat index is over 100° and it's not a lot of fun. I've been looking forward to getting this up and running for quite a while.

It sounds kind of odd, but I will sharpen and set sawmill blades on the right hand side of the room on another bench. Hopefully that won't cause too much trouble. And no, I will not store powder or primers or loaded rounds here. The only storage will be a couple hundred sawmill blades.

This year I built a new room under the same roof, but it's insulated to the max, vapor barrier, fully sealed with HVAC. I just started today framing the first workbench and it'll have a 2 inch slab top 30 in wide and 12 ft 6 long. Hopefully it'll be heavy enough that seating bullets doesn't screw up my electronic powder measure.

Now, I will be able to reload in the summertime. We have a lot of days where the heat index is over 100° and it's not a lot of fun. I've been looking forward to getting this up and running for quite a while.

It sounds kind of odd, but I will sharpen and set sawmill blades on the right hand side of the room on another bench. Hopefully that won't cause too much trouble. And no, I will not store powder or primers or loaded rounds here. The only storage will be a couple hundred sawmill blades.

Looks like a great room! Would love to have a set up like that someday.For many years I've been reloading under marginal conditions. Just a closed in room in an old equipment barn. I usually load most of my stuff in the winter when it's cold and rainy and I can't work outside. I run a sawmill business.

This year I built a new room under the same roof, but it's insulated to the max, vapor barrier, fully sealed with HVAC. I just started today framing the first workbench and it'll have a 2 inch slab top 30 in wide and 12 ft 6 long. Hopefully it'll be heavy enough that seating bullets doesn't screw up my electronic powder measure.

Now, I will be able to reload in the summertime. We have a lot of days where the heat index is over 100° and it's not a lot of fun. I've been looking forward to getting this up and running for quite a while.

It sounds kind of odd, but I will sharpen and set sawmill blades on the right hand side of the room on another bench. Hopefully that won't cause too much trouble. And no, I will not store powder or primers or loaded rounds here. The only storage will be a couple hundred sawmill blades.

View attachment 851443

49ereric

WKR

- Joined

- Jun 21, 2022

- Messages

- 1,056

Bought blemished 3 1/2” 00 buck @30 years ago. The shells leaked buffer due to poor crimps. Finally decided to fix them by cutting off the crimp and roll crimping.

Most the bad crimps shells have 17 pellets instead of 18 so adding a pellet.

Sealing with Elmer’s glue. A few crimps we good enough so just adding glue to seal.

Think I paid $2.50/box

Most the bad crimps shells have 17 pellets instead of 18 so adding a pellet.

Sealing with Elmer’s glue. A few crimps we good enough so just adding glue to seal.

Think I paid $2.50/box

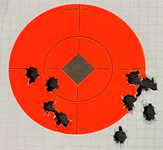

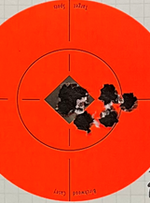

Threw together a few of my Moly slicked Barnes 112 Match Burners and now once fired ADG brass, H4831SC and CCI 200's for a test drive in a fresh Tikka 1:7.5" 6 Creed' build. Last week I ran it's first 50 rounds of Moly 105 Amax and H4350 to slick things up and grab some data out to 500 meters, It most definitely liked the good old Amax...

solarshooter

WKR

Following up on this, I finally went and shot this 162 ELDM test I loaded up.Decided to experiment with some old components in my 284 Win. Loaded 30 with 162 ELDM, IMR7828SSC, CCI200, in Lapua brass. Shot 3 groups of 6, horrendous, which was what I found last time I tested this bullet. Then shot an abbreviated Form drill with the remaining 12. Logged radius data on the second 2 groups because the first had foulers in it.

I'd like to just abandon this load completely because I already have a really good baseline, but last night I decided I might as well use this bad load to do some testing on effective methods of load dev. First, to test components I loaded up 10ea of IMR7828SSC/FED210, H4831SC/CCI200, H4350/CCI200 (all still with 162ELDM at same seating depth). This covers a different primer, and 2 different powders. Will shoot for groups of 10 and record radius data to compare which of these changes, if any, produce an improvement over the first load tested.

Then with my remaining 20 bullets, I'll do 10ea of a drastically different seating depth (currently 0.055" jump) and then a drastically different powder charge with one of the above combos to see if either of those knobs produce a meaningful result. Will edit this post with results once I do.

View attachment 840741

Mean radius for these 12 was 0.55".

First test was same IMR7828SSC powder and charge as above but switching primer to a FED210. Mean radius 0.98"!! If I look at each sub-group independently, I get 0.43" and 0.47". Overall group size is 2.5" for 10 shots, vs 1.75" for 6 in the initial test above. I don't know what happened here, either some change in my shooting input, I made a mistake in the reloading room, or this is just a real, weirdly shaped group.

What's really really weird is I shot this full test of 30 round robin style, in sets of 3/3/4 of each load, and the scatter into two groups manifested across multiple strings for this load. I would also expect whatever systematic error I had here to manifest in the other two loads, but here's the H4831SC/CCI200 group:

MR 0.33" for 10 - awesome, and a 40% improvement over the initial load.

And the H4350/CCI200 group:

MR 0.45", not great, but a 18% improvement over the initial load.

So, putting aside the very strange double group, my conclusion so far is that powder can make a HUGE difference in accuracy, but primer not so much. I'd like to hear the "nodes and harmonics don't exist" crowd explain that! No seriously, someone explain it to me - I thought precision was just proportional to recoil. Even though these are all different powders and speeds, the difference in precision is way bigger than the difference in recoil, and also not correlated.

Next up, I want to pick one of these loads and make a change in seating depth and a change in powder charge. I will also try and pick one load that I can keep constant and switch bullet, to really round out the test matrix.

Jeff Siewert explains that it's not a "harmonic" response, the barrel doesn't have a frequency like a tuning fork if you tap it with a piece of steel, but rather a forced vibration. They say it almost universally applies that dropping the powder charge can make a measurable improvement to dispersion, so some people like to call that a "node". I've never heard anything other than theory on why different powders produce different dispersion, kind of one of those unexplainable dynamics at this point.I'd like to hear the "nodes and harmonics don't exist" crowd explain that! No seriously, someone explain it to me - I thought precision was just proportional to recoil.

solarshooter

WKR

I heard him say that but I don't follow the logic or theory. I don't know enough about him to want to buy his book yet.Jeff Siewert explains that it's not a "harmonic" response, the barrel doesn't have a frequency like a tuning fork if you tap it with a piece of steel, but rather a forced vibration. They say it almost universally applies that dropping the powder charge can make a measurable improvement to dispersion, so some people like to call that a "node". I've never heard anything other than theory on why different powders produce different dispersion, kind of one of those unexplainable dynamics at this point.

What don't you follow? There's a forced vibration from a projectile being engraved upon and launched from a barrel with 65k+ psi behind it. The bore and barrel length grow, by around .0002" IIRC, so it's essentially a shockwave going down the barrel. The idea that there's a frequency, or vibrations going up and down the bore after ignition, and people being able to "time" or "tune" a load by getting it to exit at specific point of the "whip" or "oscillation" cycle, with a velocity ES of 30+, just seems like a fallacy. Probably why it's never been statistically validated too. Maybe there's something more to that when you're changing the burn rate and velocity by using a different powder.I heard him say that but I don't follow the logic or theory. I don't know enough about him to want to buy his book yet.

Pulled some bullets on old 270 Winchester ammo a cousin of mine loaded years ago. They're accurate but grandpa and I both had one that broke the ejector on our rifles. Cousin said he thought he used 4831 but when I pulled em it was a ball powder. Gonna have to pull and ditch the powder on em all I guess cause he can't recall exactly what he used and I don't want to blow up anymore guns

solarshooter

WKR

I misspoke in my post above. I follow his theory, I just didn't see him go in depth or explain any test or evidence of this theory being correct.What don't you follow? There's a forced vibration from a projectile being engraved upon and launched from a barrel with 65k+ psi behind it. The bore and barrel length grow, by around .0002" IIRC, so it's essentially a shockwave going down the barrel. The idea that there's a frequency, or vibrations going up and down the bore after ignition, and people being able to "time" or "tune" a load by getting it to exit at specific point of the "whip" or "oscillation" cycle, with a velocity ES of 30+, just seems like a fallacy. Probably why it's never been statistically validated too. Maybe there's something more to that when you're changing the burn rate and velocity by using a different powder.

This book https://archive.org/details/RifleAccuracyFactsFullV1.0FirstFullScan/page/n53/mode/2up contains theoretical, simulation, and experimental results that indicate that barrel modes do indeed exist and impact precision.

Like I said, I think I need to read Jeff's book to really get into the meat of his theory and evidence. I just haven't yet.

OMG.Pulled some bullets on old 270 Winchester ammo a cousin of mine loaded years ago. They're accurate but grandpa and I both had one that broke the ejector on our rifles. Cousin said he thought he used 4831 but when I pulled em it was a ball powder. Gonna have to pull and ditch the powder on em all I guess cause he can't recall exactly what he used and I don't want to blow up anymore guns

OMG? OMG what?OMG.

Pharmseller

WKR

Lawnboi

WKR

Similar threads

- Replies

- 11

- Views

- 686

Featured Video

Latest Articles

- How Old Was He Really? Big Buck Hunters Talk Age vs. Score

- Banning Hunting Technology in Idaho?

- Best Gear of the year Rokslide staff edition 2025 Article

- Hunting Gear: Insights from Western Hunting Expo

- Black Diamond Alpine Start Insulated Hoody Review

- Tenacity Firearms with Andrew Whitney

- The Thrill of Moose Hunting with Henry Ferguson

- Final Rise Upland Hand Muff Review

- Kodiak Deer Hunt Round II

- Killing a Timber Giant