Well you didn't blame it all on user abuse and carry on as normal so it doesn't sound like SiCo.There have been issues with larger cartridges like 300 WSM 300 win mag with the tikka rings. It has to do with rifle weight, scope weight, amount of powder, etc. But some have been slipping and pushing the pins.

The pins are steel, but soft.

There are slight redesigns in the works at the moment. And when proven out they will hold up to whatever you can run with a Tikka action.

Not to sound like Silencer Co with the Scythe, but the problem is much less than 1%.

Ken

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

UM Tikka rings are not recommended for cartridges larger than 7mm PRC?

- Thread starter Cdnance

- Start date

Good to hear.

I have to agree with @SDHNTR that using a cartridge leaves a lot of ambiguity In the benchmark. Specifying a recoil impulse as well would be helpful as that accounts for rifle weight, charge weight, and bullet weight much better than a head stamp.

Have you thought about redesigning the pins to be more like a socket head screw? Have them sit lower, the head would support the shaft and avoid bending, and the friction between the head and top of the rail should protect the screw from some of the sheer forces. A #6 48 round socket cap screw would probably work.

Of course, the slots in the ring bases would need modification.

Your thought process is solid, this is one of the things that were tested! The thru bolt for the clamp caused interference with this unfortunately.

Ken

Yeah but that would be an individual issue, not a manufacturing issue.From what I have seen, people don't torque them correctly.

In this instance the manufacturer is stating they are not recommended for anything over 7 PRC. Makes me wonder if they just simply can’t handle the recoil on either the rail or scope.

If it is less than 1% would you recommend I put these on a 300 WM? From what you’re saying I have over 99% chance that they will be fine. Right?There have been issues with larger cartridges like 300 WSM 300 win mag with the tikka rings. It has to do with rifle weight, scope weight, amount of powder, etc. But some have been slipping and pushing the pins.

The pins are steel, but soft.

There are slight redesigns in the works at the moment. And when proven out they will hold up to whatever you can run with a Tikka action.

Not to sound like Silencer Co with the Scythe, but the problem is much less than 1%.

Ken

I was talking to a hunting partnet last week as he was asking for ring recommendation for his two Tikkas. He mentioned the part about limitations for cartridges larger than 7PRC as he got it from ChatGPT. I told him ChatGPT was wrong and he needs to go to the website and see it’s not factual. It turns out I was wrong as it is on there. Needless to say, he’s not getting UM rings for his 300.WM, which means he won’t get them for his smaller caliber as well as he wants things the same for both rifles.

- Joined

- Oct 22, 2014

- Messages

- 14,558

Pretty sure the issue was first brought up by me. It is caused by not enough torque on the base bolts and not pushing the ring forward against the pin when tightening. At 65in-lbs they have not slipped with way more recoil than a 7PRC. UM is uncomfortable with blanket stating that 65in-lbs is the way- not sure why, but that’s it. They are working on an updated clamp design.

This is not UM speaking, this is me:

This is not “something was wrong”. with the UM tikka rings. They are the strongest rings on the market that use the integral dovetail. It’s that the dovetail itself needs a high clamp force and to hold with repeated recoil- this is true of ALL the dovetail tikka rings. UM is finding a solution to make them better than they are- that’s it. Don’t make a mountain out of a mole hill- mount them as I state below and go shoot.

50in-lbs is not enough to hold the base in place. Degrease everything, thread lock, push forward on the ring against the pin, torque to 60 or 65in-lbs on the base screws. Go shoot.

This is not UM speaking, this is me:

This is not “something was wrong”. with the UM tikka rings. They are the strongest rings on the market that use the integral dovetail. It’s that the dovetail itself needs a high clamp force and to hold with repeated recoil- this is true of ALL the dovetail tikka rings. UM is finding a solution to make them better than they are- that’s it. Don’t make a mountain out of a mole hill- mount them as I state below and go shoot.

50in-lbs is not enough to hold the base in place. Degrease everything, thread lock, push forward on the ring against the pin, torque to 60 or 65in-lbs on the base screws. Go shoot.

Sundodger

WKR

There have been issues with larger cartridges like 300 WSM 300 win mag with the tikka rings. It has to do with rifle weight, scope weight, amount of powder, etc. But some have been slipping and pushing the pins.

The pins are steel, but soft.

There are slight redesigns in the works at the moment. And when proven out they will hold up to whatever you can run with a Tikka action.

Not to sound like Silencer Co with the Scythe, but the problem is much less than 1%.

Ken

Pretty sure the issue was first brought up by me. It is caused by not enough torque on the base bolts and not pushing the ring forward against the pin when tightening. At 65in-lbs they have not slipped with way more recoil than a 7PRC. UM is uncomfortable with blanket stating that 65in-lbs is the way- not sure why, but that’s it. They are working on an updated clamp design.

This is not UM speaking, this is me:

This is not “something was wrong”. with the UM tikka rings. They are the strongest rings on the market that use the integral dovetail. It’s that the dovetail itself needs a high clamp force and to hold with repeated recoil- this is true of ALL the dovetail tikka rings. UM is finding a solution to make them better than they are- that’s it. Don’t make a mountain out of a mole hill- mount them as I state below and go shoot.

50in-lbs is not enough to hold the base in place. Degrease everything, thread lock, push forward on the ring against the pin, torque to 60 or 65in-lbs on the base screws. Go shoot.

If I remember correctly when I got my rings the bolts that clamp the dovetail were a larger diameter than sportmaches I have used before. In this re-design I would recommend to look into joint relaxation, I didn't take any measurements but it sure looked like a worse D/L ratio compared to sportmatches. Three or four smaller diameter bolts might be a better solution that two big ones that are too sensitive to real world installation.

I can see why going to 65 inch pounds worries people, Not sure what tensile load you guys are targeting, but the higher the probability of exceeding 75% proof load means more chance for messiness especially with aluminum under the bolt head. The torque to tension relationship up there is noisy and with selling tons of these things to tons of people who do tons of installs you want the bell curve of your final bolt tension to fall between what's minimum load needed to keep the joint together and whatever max load keeps all the high tension problems away (galling, yielding, etc.).

I am glad that you guys are looking to fix the joint rather than a Band-Aid fix like just make a stronger pin. In the fastener world a joint where tensile loads are exceeded is a failed joint even if it didn't come apart yet (don't worry, it will eventually).

If I remember correctly when I got my rings the bolts that clamp the dovetail were a larger diameter than sportmaches I have used before. In this re-design I would recommend to look into joint relaxation, I didn't take any measurements but it sure looked like a worse D/L ratio compared to sportmatches. Three or four smaller diameter bolts might be a better solution that two big ones that are too sensitive to real world installation.

I can see why going to 65 inch pounds worries people, Not sure what tensile load you guys are targeting, but the higher the probability of exceeding 75% proof load means more chance for messiness especially with aluminum under the bolt head. The torque to tension relationship up there is noisy and with selling tons of these things to tons of people who do tons of installs you want the bell curve of your final bolt tension to fall between what's minimum load needed to keep the joint together and maybe 80% proofload depending on a bunch of things.

I am glad that you guys are looking to fix the joint rather than a Band-Aid fix like just make a stronger pin. In the fastener world a joint where tensile loads are exceeded is a failed joint even if it didn't come apart yet (don't worry, it will eventually).

Reading this reply, you can look at the dovetail size on the tikka, the bolts being used, and be able to tell why they could potentially fail if not installed exactly how they are recommended to. I normally don't go super in depth on stuff unless someones asking questions more like these.

Ken

I would read it as the manufacturer finds a less than 1% failure rate unacceptable, so they have recommended restrictions to reduce that rate while working on correcting the issue from a design perspective.If it is less than 1% would you recommend I put these on a 300 WM? From what you’re saying I have over 99% chance that they will be fine. Right?

Which, in my opinion is a solid and appropriate response.

You, as the user, can choose to accept the risk, but the outcome is on you.

Keysbowman

FNG

I bought my UM Rings in April this year . Mounted them per instructions on .300WM and shot the rifle every week up to my NM Elk hunt. Held zero the whole time and I experienced no issues.

- Joined

- Oct 22, 2014

- Messages

- 14,558

Are the caps still good at the recommended 30 in-lbs?

28in-lbs for thin scopes tubes- Leupold, Vortex, Swarovski, etc. 32in-lbs for good ones- Nightforce, SWFA, Trijicon, etc.

Same advice for Sportsmatch? Cap torque values too?50in-lbs is not enough to hold the base in place. Degrease everything, thread lock, push forward on the ring against the pin, torque to 60 or 65in-lbs on the base screws. Go shoot.

*edited to add*

- Joined

- Oct 22, 2014

- Messages

- 14,558

Same advice for Sportsmatch? Cap torque values too?

*edited to add*

I go “tight” by feel on Sportsmatch bases. Then, 20-25 in-lbs on the ring caps.

Sundodger

WKR

Haha, I wish I had that kind of engineering crystal ball. But I worked long enough designing joints (some real nasty ones too), that I know the fundamentals so can give some directional information. Increase bolt size and not increasing bolt stretch length and your D/L ratio is worse, which is worse for joint relaxation and margin of error on torque. If the D/L is still within acceptable bounds then I might would look elsewhere, but the fact they are having to go to 55inlbs+ on a bolt that small is a red flag that the joint isn't robust.Reading this reply, you can look at the dovetail size on the tikka, the bolts being used, and be able to tell why they could potentially fail if not installed exactly how they are recommended to. I normally don't go super in depth on stuff unless someones asking questions more like these.

Ken

Basically if you are having to wring every little bit out of those bolts to have a secure joint means trouble statistically. Especially since they are not marketed as "racer light", where there is an argument for exotic things when that's the goal.

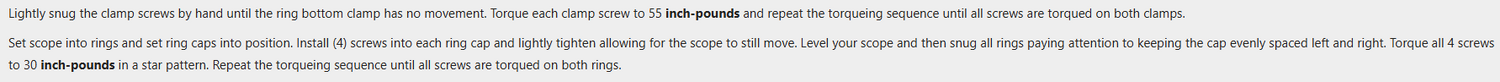

This summer while installing them, I noticed a discrepancy. The website and video have two different torque specs. Gave them a call and had a good chat with one of the builders at UM.Looks like the recommended torque spec has increased. Video says 45 in-lbs on the bases and 25 in-lbs on the caps...which is what I currently have on my Tikka.

Description now shows...

View attachment 961151

He said they’d get that fixed. Never checked again since I installed mine at the higher torque.