Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ULUL Stainless/Portless 6x45 16" AR15 Barrel Group Buy NOW CLOSED

- Thread starter PistolPete

- Start date

FWIW, PT&G's current drawing of their 6x45 reamer is yours, not something with larger dimensions. Don't know if they made something different for Satern or if there was some other issue with the chambering process if that's the issue.

Yes. That’s correct.

Turns out my ignorance and our busted first attempt at a stub job on the handi may have helped figure out the issue

PistolPete

WKR

- Joined

- Dec 6, 2019

- Messages

- 453

Hey all, just heard from Stu at Satern:

Good afternoon Peter, I just got off the phone with Kyle. He brought me some information today and I showed the boss, it turns out there has been a revision on the 6x45 print with Saami that we were unaware of. So we have been running a chamber reamer that was made to the original print. Thanks to Kyle, he sent me a print of the reamer he bought and had a barrel fixed with. I'm holding on to the remaining barrels to see if we can fix them with an Alpha reamer when we get it. I can assure you we will take care of this and you all won't be left out there flapping in the wind. If you want to reach out to your crew and let them know, that would be great!Looking forward to having this resolved and everybody walking away happy.

Thanks, Kyle!

Good afternoon Peter, I just got off the phone with Kyle. He brought me some information today and I showed the boss, it turns out there has been a revision on the 6x45 print with Saami that we were unaware of. So we have been running a chamber reamer that was made to the original print. Thanks to Kyle, he sent me a print of the reamer he bought and had a barrel fixed with. I'm holding on to the remaining barrels to see if we can fix them with an Alpha reamer when we get it. I can assure you we will take care of this and you all won't be left out there flapping in the wind. If you want to reach out to your crew and let them know, that would be great!Looking forward to having this resolved and everybody walking away happy.

Thanks, Kyle!

Jesseb

WKR

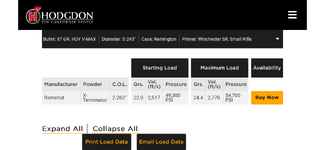

Wow, pleasantly surprised! Hope a new reamer fixes it. Unfortunately I just finished loading up more rounds to go give it another go with the load posted earlier. 87 vmax over 24.2 Tac @ 2.280”. Also loaded 5 @ 2.375” (.020” jump) and 5 @ 2.280” over 24.2 of 8208xbr. I guess I could hold onto them for break in and testing of a new replacement barrel should they send me one.Hey all, just heard from Stu at Satern:

Good afternoon Peter, I just got off the phone with Kyle. He brought me some information today and I showed the boss, it turns out there has been a revision on the 6x45 print with Saami that we were unaware of. So we have been running a chamber reamer that was made to the original print. Thanks to Kyle, he sent me a print of the reamer he bought and had a barrel fixed with. I'm holding on to the remaining barrels to see if we can fix them with an Alpha reamer when we get it. I can assure you we will take care of this and you all won't be left out there flapping in the wind. If you want to reach out to your crew and let them know, that would be great!Looking forward to having this resolved and everybody walking away happy.

Thanks, Kyle!

Sounds like progress, but I'm not seeing how a smaller reamer is going to fix an oversize chamber on an already finished barrel. I wouldn't think there would be enough shoulder length and barrel length left to re-chamber to smaller dimensions. I'd think a smaller reamer would have to go a neck length deeper to fix that part. OTOH, I'm not a barrel maker, so there is that...Hey all, just heard from Stu at Satern:

Good afternoon Peter, I just got off the phone with Kyle. He brought me some information today and I showed the boss, it turns out there has been a revision on the 6x45 print with Saami that we were unaware of. So we have been running a chamber reamer that was made to the original print. Thanks to Kyle, he sent me a print of the reamer he bought and had a barrel fixed with. I'm holding on to the remaining barrels to see if we can fix them with an Alpha reamer when we get it. I can assure you we will take care of this and you all won't be left out there flapping in the wind. If you want to reach out to your crew and let them know, that would be great!Looking forward to having this resolved and everybody walking away happy.

Thanks, Kyle!

Jesseb

WKR

These barrels can not be re-chambered. They would have to replace the barrels.

robtattoo

WKNR

Kinda regretting telling Deb I wouldn't send mine back now.These barrels can not be re-chambered. They would have to replace the barrels.

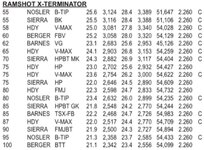

I tried 2 other powders today, just to check velocity.

24.1gr IMR4895 = 2277 (3 shot average)

24.5 Norma 202 (4064 equiv) = 2389 (3 shot average)

No pressure signs at all. The Norma looks promising, maybe around 26gr (which would be about right, since it's discontinued

I would agree with you that the shoulder should have been what hit. But it was Like the top of the neck was hitting a rifling. It almost seemed more like a concentricity problem….. but a different bolt fixed it.AR bolts absolutely vary a little, but this explanation from X-Caliber doesn't quite make sense. If the Solo bolt left too little headspace to chamber a fully sized case, which is possible, the case shoulder would still prevent it from running a bullet into the lands(??). That's almost solely a function of bullet seating depth.

Here is my reamer print from a couple years ago:View attachment 6x45 std.pdf

I would be surprised if a slight difference in chamber spec is causing big groups. That is normally an inconsistent groove diameter throughout the length of the barrel.

I would be surprised if a slight difference in chamber spec is causing big groups. That is normally an inconsistent groove diameter throughout the length of the barrel.

Jesseb

WKR

Not saying you are wrong, entirely possible. But, here is my theory. A combination of an excessively large neck and long freebore means that gases are likely getting out and around the bullet and thus in front of it before it engages the rifling which leads to the lackluster velocity we are seeing and the inaccuracy. The fact that I can go pretty far over max loads without pressure signs would also support this. I do not think that anyone after accuracy wants neck growth in the .008-.010” range. AND, if I load even the vmax to standard AR coal of 2.260” I would have .135” jump. Tmk would be .320”!! Loading the vmax to .010” jump didn’t help however.Here is my reamer print from a couple years ago:View attachment 954382

I would be surprised if a slight difference in chamber spec is causing big groups. That is normally an inconsistent groove diameter throughout the length of the barrel.

Now with that said, before my last outing I cleaned the barrel with a copper fouling remover. After a thorough cleaning I noticed I could see what appeared to be slight copper fouling on the edges of the rifling near the muzzle. I was already committed to heading out to try some new loads after getting my Redding type S bushing die and figured I was maybe headed in the right direction so I figured it at least had to be better than before. The damn thing shot worse than ever!

The only other explanation would be that the stainless they use is not as good as what Shaw is using and therefore needs to be of thicker wall to yield similar performance. In theory, wall thickness kept the same, the larger the diameter the stiffer so that shouldn’t be it, but perhaps they simply do not have the quality of SS that Shaw does? I tried waiting 3-4 minutes between shots with the 87 vmax the other day and got the same terrible results. I mean, even the cheap BCA pencil barrels are known to be better than 2moa shooters!

Of special interest, most of my groups have been mostly vertical stringing in the 2-4” range, even with good es and sd numbers. Not sure what to think of that.

Here is my reamer print from a couple years ago:View attachment 954382

I would be surprised if a slight difference in chamber spec is causing big groups. That is normally an inconsistent groove diameter throughout the length of the barrel.

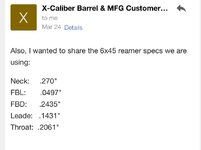

The reamer you’re using has an even tighter neck than mine (.270, +.001tolerance versus (.270+.003tolerance).

And what may be a shorter “distance to lands” than mine by way of a shorter leade.

I would expect the reamer you have to produce far better accuracy results than whatever Satern was using, and probably better than my new PTG reamer.

The unanswered question is “how did Satern’s 6x45 barrels of the past shoot with what we should assume are sub 85gr bullets, in AR mag length from AR’s?”

I suspect if they shot poorly, there’d at least be some internet evidence of it. I haven’t found it, and Satern hasn’t gotten that feedback.

This may mean that the first run of barrels aren’t worthless. The reamer didn’t go bad. The chamber is to spec. It’s just a “not ideal” spec.

Sounds like they’re going to straighten it out with a tighter neck dimension and shorter freebore.

X caliber jgs reamer just for reference. View attachment 954448

I have a X-Cal prefit 6x45 on a bolt gun. It’s a good barrel. The brass interchanges with my other one that was reamed with the Manson above with no problems.

I’ll say the quiet part aloud, with all due respect to hurt feelings: a $170 barrel is a crap shoot. It sounds like Satern is interested in helping you guys out, and that’s a real bonus. Hope it works out.

Jesseb

WKR

You are not wrong! I am an engineer so I start with the obvious. There is zero doubt that my chamber is out of spec. So I would start there. Rather that’s part of the $170 crap shoot or not, I don’t know. Sounds like they drill and rifle their barrels in house so maybe they got that part wrong? or maybe it’s a steel quality issue?I have a X-Cal prefit 6x45 on a bolt gun. It’s a good barrel. The brass interchanges with my other one that was reamed with the Manson above with no problems.

I’ll say the quiet part aloud, with all due respect to hurt feelings: a $170 barrel is a crap shoot. It sounds like Satern is interested in helping you guys out, and that’s a real bonus. Hope it works out.

You are not wrong! I am an engineer so I start with the obvious. There is zero doubt that my chamber is out of spec. So I would start there. Rather that’s part of the $170 crap shoot or not, I don’t know. Sounds like they drill and rifle their barrels in house so maybe they got that part wrong? or maybe it’s a steel quality issue?I have built 2 rifles using Satern barrels in 6.5 Grendel and both shoot great. My Shaw ulul portless was sub $200 and shoots great. Factory savage axis .270 sporter cost me $270 for the whole rifle and shot great, tossed an x-caliber 280ai barrel on it and still shot great. We really haven’t heard of one of these barrels shooting well at any decent velocity but not sure too many of the barrel owners have shot theirs yet. Maybe it’s just the few of us that have shot them that got shitty barrels. The only group posted was all vertical which is what I have been seeing, only mine were much larger!

I am not an engineer

I have screwed on my share of barrels, chambered a good many of them. Still do a couple a year which is just enough to make it hard to remember what I did successfully or failed at last time. lol. I have reamed chambers for the PPC family and the 06 family that have tight necks and require neck turning. Pain in the ass, not worth it for a hunting gun. Give me a little sloppy neck. I like a short leade, I’m a dinosaur. I do have a rifle or two that doesn’t mind a .120 jump though. Go figure.

I really like Hart. Good family. They actually charge a little premium for a ultralight barrel, Remington Mountain Rifle contour as an example. X-Cal limits length on their lightweight to 22” I think it is, guess it’s harder to make a skinny one consistent. The cheapest barrel I’ve used is made by Wilson barrels. They machine hard but shoot well.

left hunter

Lil-Rokslider

- Joined

- Feb 6, 2013

- Messages

- 251

So for folks like me that bought a barrel and haven’t shot it (or even plan on messing with it until after hunting season), what is the best course of action? Not sure I really want to load ammo and burn it up if the chamber is already known to be bad

And has anybody confirmed they are going to replace the improperly chambered barrels or is that just speculation at this point?

And has anybody confirmed they are going to replace the improperly chambered barrels or is that just speculation at this point?

My xcaliber barrel shot necks are around .269What did the neck dimension of the chamber casting measure?

.270” is what it should be. I don’t see how you’re getting .275” fired neck measurements if your chamber neck is in spec.

@ezwy can you measure neck on fired rounds from your barrel?

Satern is around .2725

robtattoo

WKNR

I know it's an inconvenience, but please, load up 30-50 rounds & shoot it. Load to book values so we have a known velocity data line.So for folks like me that bought a barrel and haven’t shot it (or even plan on messing with it until after hunting season), what is the best course of action? Not sure I really want to load ammo and burn it up if the chamber is already known to be bad

And has anybody confirmed they are going to replace the improperly chambered barrels or is that just speculation at this point?

The more results we have, the better the chances of Satern putting it right.

robtattoo

WKNR

Ok, now I really wish I hadn't apologized to Deb & declined to send my barrel back.

She emailed me yesterday & mentioned that I might want to mention to the rest of the group that my chamber IS to spec, per my measurements.

I'm starting to get a little confused as to whether my chamber is correct, or correct to a different spec reamer, or I'm just shit at measuring, or I just can't weigh powder & shot properly, or my chronograph is busted or what.

Unless I get direct instructions telling me to send it back (via Pete, or here, or an email) I'm pretty sure I'm out $170

She emailed me yesterday & mentioned that I might want to mention to the rest of the group that my chamber IS to spec, per my measurements.

I'm starting to get a little confused as to whether my chamber is correct, or correct to a different spec reamer, or I'm just shit at measuring, or I just can't weigh powder & shot properly, or my chronograph is busted or what.

Unless I get direct instructions telling me to send it back (via Pete, or here, or an email) I'm pretty sure I'm out $170

Similar threads

- Poll

- Replies

- 47

- Views

- 2K

- Replies

- 474

- Views

- 24K

- Replies

- 184

- Views

- 15K

Featured Video

Latest Articles

- How Old Was He Really? Big Buck Hunters Talk Age vs. Score

- Banning Hunting Technology in Idaho?

- Best Gear of the year Rokslide staff edition 2025 Article

- Hunting Gear: Insights from Western Hunting Expo

- Black Diamond Alpine Start Insulated Hoody Review

- Tenacity Firearms with Andrew Whitney

- The Thrill of Moose Hunting with Henry Ferguson

- Final Rise Upland Hand Muff Review

- Kodiak Deer Hunt Round II

- Killing a Timber Giant

I have built 2 rifles using Satern barrels in 6.5 Grendel and both shoot great. My Shaw ulul portless was sub $200 and shoots great. Factory savage axis .270 sporter cost me $270 for the whole rifle and shot great, tossed an x-caliber 280ai barrel on it and still shot great. We really haven’t heard of one of these barrels shooting well at any decent velocity but not sure too many of the barrel owners have shot theirs yet. Maybe it’s just the few of us that have shot them that got shitty barrels. The only group posted was all vertical which is what I have been seeing, only mine were much larger!

I have built 2 rifles using Satern barrels in 6.5 Grendel and both shoot great. My Shaw ulul portless was sub $200 and shoots great. Factory savage axis .270 sporter cost me $270 for the whole rifle and shot great, tossed an x-caliber 280ai barrel on it and still shot great. We really haven’t heard of one of these barrels shooting well at any decent velocity but not sure too many of the barrel owners have shot theirs yet. Maybe it’s just the few of us that have shot them that got shitty barrels. The only group posted was all vertical which is what I have been seeing, only mine were much larger!