@B_Reynolds_AK,

@PC356,

@Bowfinn

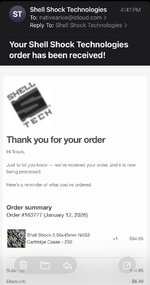

Just got off the phone with Shell Tech about the NAS3 5.56 cases. It shows back order, but from what he told me, cases are coming in, so orders should ship pretty quick.

He was a nice guy, and took a few minutes to answer my questions. Figured I’d pass it on here.

Reloadability: Cases are not reloadable at the moment, but he will be bringing out the sizing die at some point, and then they will be reloadable. He said it may be the end of the year before he gets around to designing it and bringing it out. With this being the case, I’d hang onto my fired cases.

Finding pressure: According to him, the case heads will handle up to 250,000 psi, so they don’t show pressure. They won’t blow primers. The sign of too much pressure is when you’re piercing primers. This happens somewhere between 80k and 100k psi. Obviously, we know that some primers have weaker cups than others, so do with that what you will.

Neck lube: I asked about the possibility of needing to use neck lube on new cases. He said this is not necessary. Just prime, charge, and seat bullets in new cases and go.

Neck crimp: Using a Lee FCD is mentioned on their site. He said this is not really necessary. With the stainless, you can cause a super high bullet pull pressure if you do this. It’s also semi difficult to get a perfectly symmetrical crimp, and because of that it can reduce accuracy.

Increased case capacity: 5.56 cases will have 8-10% increased case capacity over standard brass, with larger cases being up to 12%. Because of this, velocity and pressure will be lower if you bring over your existing load from brass cases. If you’re using a slow powder for your cartridge and bullet combo, you may find an advantage by switching to a slightly faster burning powder to hit pressure and case fill at the optimal points.

Hope y’all find this information helpful!