- Joined

- Apr 15, 2023

- Messages

- 146

Im just glad to see you doing some sort of load work

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I’ll absolutely be testing different seating depths, charge weights and even powders at some point.If you wouldn’t mind sharing, what is your process for once fired brass as well? Also will you be doing any type of load development, like testing different powder charges or seating depths or is this mostly about testing different case prep. Thanks for doing this, will be following along

Interesting, I always assumed the case might stretch a bit after sizing so I’ve just FL sized then trimmed and chamfered, thats just the way I was taught and never thought about it differently thoughSomething I normally do once all my brass is once fire though, is run it all through the Henderson trimmer before I FL size, to the get the COAL’s all exactly the same. Then I don’t trim them again generally.

Yeah, if it’s consistent before, it’ll be consistent after. In my instance, all cases trimmed to match and then sized the same. The opposite is also true. Could easy do it the other way around as far as consistency is concerned.Interesting, I always assumed the case might stretch a bit after sizing so I’ve just FL sized then trimmed and chamfered, thats just the way I was taught and never thought about it differently though

Very cool!What I’m calling the 22 creedmoor project, has started.

The gun was built by @barehandlineman at High Voltage Armory.

1-8 twist 24” Heavy Palma Muller Works

Defiance SA HVA Exodus Action

MDT XRS Chassis

Bix N Andy tac sport pro trigger

Area 419 Hunt Rings. .94”

Trijicon Tenmile HX 5-25X50 MOA FFP

Scoped rifle weighs 14.56lbs. No muzzle threads.

View attachment 805599

This is just a data collection driven project. I will document as much as I can and share openly. Nothing hidden or knit picked.

I really want to personally learn as much as I can about shooting (especially positional and building effective positions) & reloading and what affects what, and by how much (if any). Also barrel life/wear and how it affects speeds/groups as the shot count grows.

I used my normal virgin brass prep and a load that worked well in my last barrel and loaded up 50 rounds. This is my “Control” load and groups. A generic baseline basically.

Alpha LRP brass

80 ELDM

41gr. H4350

CCI 200

2.660” COAL

I bore sighted the gun. Shot 3. Adjusted over. Shot 10. Aim point was black “X”.

View attachment 805600

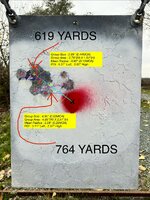

I adjust right 1/4 and down 1/2. Scrubbed the barrel clean. Shot some foulers out of the group. Then shot 20 straight rounds for a group. No breaks other than swapping mags. This is my control group for future comparisons when testing.

View attachment 805602

I then went to 471 yards and shot 10 for a group to see how the load held up. There was a 5-10 MPH wind the whole range session. I did not hold for wind intentionally, so that I wouldn’t shoot out my aim point. Just testing the loads precision at a decent distance. It is trending high, but I’ll correct the data at 800-1000 yards later on.

View attachment 805604

Every one of these rounds was weighed within 1 kernel on an A&D FX 120i scale. This was the ES & SD over 25 rounds in virgin brass.

View attachment 805607

View attachment 805608

I have 500 pieces of the same lot of Virgin alpha brass. An 8lb of H4350. 1100 80 ELDMS of the same lot number. So testing can be consistent throughout.

View attachment 805605

View attachment 805606

A lot of this testing will be done for myself and my own curiosities. But I’m also considering this a community 22 CM. So if you have valid interests that you would like to see tested, and they’re reasonable to do, please share them and I’ll try to accommodate those interests as well!!

Also these new area 419 rings seem absolutely first class.

View attachment 805610

All animals you see killed in CA were shot with a random copper load. Just close range coyotes mostly in the future. All practing and target shooting will be mostly with 80 ELDM’s.

FYI, the chassis and donkey dick of a barrel were just selected because they were cheap, and available lol. Chassis seems nice to shoot behind and has a comfortable grip. Definitely plastic feeling and flimsy feeling. But I’m honestly not that critical of things anyways. It seems nice enough for $550.

I went to the 80’s because I like ELDM’s and 1-8 twist barrels was all that was available. I also like speed, and I don’t plan to hunt big game animals with it. Just coyotes and pigs.Very cool!

I'm a still waiting on my 22 cal barrel blank to put mine together.

Couple questions, what made you skip over the 88's or even the Berger 85's?

Which reamer/freebore did you choose?

Also, I don't know if you run the SAC modular sizer but If you want to save time and remove a step, their sizer with a mandrel is really sweet. I've tested it for SD and ES as well as seating force with alpha creedmoor brass and there was no observable difference between the SAC die w/mandrel and running an expander mandrel as a final step before seating.

Hahaha excellent!!!@huntnful I’ll be the control when I start loading for my 22 CM. I don’t do sh!t.

Nothing yet with this charge. But in all honestly I’m running the bolt pretty good and not solely focusing on the bolt lift. I’ll take pictures of the case heads when I get home from duck hunting, and pay a little more attention to the bolt on the next trip. But nothing significant enough to me to even really pay attention to it yet with 41gr. H4350.@huntnful Have you felt any heavy bolt lifts or “clickers” with this load yet?

De-prime

Imperial Lube case

FL size

Wipe off lube

Bush/moly necks.

Expand with mandrel

Prime

I almost think the simplicity will work so good, I’m scared to try itFirst off, this project is a pretty awesome idea and extremely generous of you.

I'm currently doing about the same process on fired brass as yours quoted. Multiple passes through the press, not to mention wiping die wax and applying moly is tedious.

Some days I dream up the idea of getting a SAC size die with the mandrel/decap pin, spray cases with oneshot, one stroke on the press and call it a day.

Would be interesting to test something similar, depending on what you have for dies.

Thank you very much for bringing this to my attention dude. I prepped two set of virgin brass with your recommendation. One set I just brushed, and the other set I brushed and used moly.With that said I don’t think those seating forces are a product of overly tight interference fit, but friction of the squeaky clean annealed neck. Same thing can be seen with brass that has been squeaky clean tumbled and then annealed. On alpha you can feel the grittiness of that annealed area.

I do very similar to you, and maybe worth a try.

After seeing how well the Virgin brass shot after just brushing the necks, I decided to prep 100 of the once fired cases with basically what you said here. Except I lubed them manually and just wiped it off afterwards.First off, this project is a pretty awesome idea and extremely generous of you.

I'm currently doing about the same process on fired brass as yours quoted. Multiple passes through the press, not to mention wiping die wax and applying moly is tedious.

Some days I dream up the idea of getting a SAC size die with the mandrel/decap pin, spray cases with oneshot, one stroke on the press and call it a day.

Would be interesting to test something similar, depending on what you have for dies.