jpndave

FNG

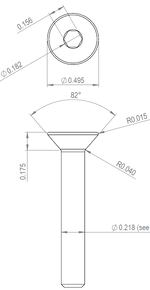

@Wrangler13 Nice! Kampfeld has done the cuts for the ejector clearance. Still smooth over a full mag? Do you feel those flutes at all?View attachment 664840Here are some pics of my kampfeld fluted bolt.

Last edited:

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

@Wrangler13 Nice! Kampfeld has done the cuts for the ejector clearance. Still smooth over a full mag? Do you feel those flutes at all?View attachment 664840Here are some pics of my kampfeld fluted bolt.

Pretty sure LRI (or Kampfeld) can knock off more weight with their spiral flutes than the Ascent has. My 22 creed ascent/hunter/swiss cheese still easily shoots sub MOA and I don't think you can beat the looks, and grippyness of the spiral flutes. Here's the pic again for reference.

Does anyone know how much weight the member that posted pics of ti screws on a scale actually saved? I looked at that post more than once and never came away with a solid understanding of how much he shaved off. Probably because I didn't know what I was looking at in the pic...I don't know if he can do it, but I sent Chris (the guy on 24hr that does the ti bolt handles) a message to see if he could make ti action screws for the Hunter.

I told him guessing there would be some interest.

I dont know about the kimber action screws exactly, but on my Tikkas, the factory steel screws are 15.4 grams and the ti replacements are 9 grams for the pair.Does anyone know how much weight the member that posted pics of ti screws on a scale actually saved? I looked at that post more than once and never came away with a solid understanding of how much he shaved off. Probably because I didn't know what I was looking at in the pic...

I have titanium action screws in the works if anyone is interested. They won't be the goofy long extended head though so on the Hunter they would be up inside the stock a bit on the rear screw. Also a T25 Torx head.I dont know about the kimber action screws exactly, but on my Tikkas, the factory steel screws are 15.4 grams and the ti replacements are 9 grams for the pair.

Does anyone know how much weight the member that posted pics of ti screws on a scale actually saved? I looked at that post more than once and never came away with a solid understanding of how much he shaved off. Probably because I didn't know what I was looking at in the pic...

I have titanium action screws in the works if anyone is interested. They won't be the goofy long extended head though so on the Hunter they would be up inside the stock a bit on the rear screw. Also a T25 Torx head.

I'd be interested as wellI have titanium action screws in the works if anyone is interested. They won't be the goofy long extended head though so on the Hunter they would be up inside the stock a bit on the rear screw. Also a T25 Torx head.

Titanium is ~60% the weight of steel. The rear screw will be quite a bit less as that shank is fat so -40% of the front and -all of the fat shank and then 40% of what is left after that on the rear for a Hunter. Wood/Montana/Ascent ~-40%. I am getting ready to order the blanks for the screws which I will shorten & contour the heads in my lathe. They aren't cheap but they are coolI think he only had the shorter screw?- it showed 16 grams vs 5 grams for the ti one

I'm interested as well, cost dependent. Just to clarify, you're making them for the hunter or the Ascent, or both? I know the Ascent screws are significantly longer, or at least one of them is.Titanium is ~60% the weight of steel. The rear screw will be quite a bit less as that shank is fat so -40% of the front and -all of the fat shank and then 40% of what is left after that on the rear for a Hunter. Wood/Montana/Ascent ~-40%. I am getting ready to order the blanks for the screws which I will shorten & contour the heads in my lathe. They aren't cheap but they are cooland grams lighter.

Not sure, I'm still confused. But, I guess this is less crazy than me spending 6-8 hours skeletonizing the mag!I think he only had the shorter screw?- it showed 16 grams vs 5 grams for the ti one

If anyone has a set of hunter screws ,I’m in BC and they are unobtanium.

I swapped my Adirondack into a second hand degelled Hunter stock and I robbed the screws from my Hunter. Thx kelly

I'll have multiple sets of those when I swap these rifles out of their stocks but they might need to stay with the stocks... or I guess I could run the TI Screws. Might need to bring in a few shorter ones I guess...If anyone has a set of hunter screws ,I’m in BC and they are unobtanium.

I swapped my Adirondack into a second hand degelled Hunter stock and I robbed the screws from my Hunter. Thx kelly

Lol, I gave mine away, it was 0.1 oz, so I HAD to do it...So I noticed yesterday in my safe, and then just checked my pic on page 23 with the buck, my rifle took it upon itself to get even lighter as my grip cap is missing lol. Probably won't bother replacing it.

So I noticed yesterday in my safe, and then just checked my pic on page 23 with the buck, my rifle took it upon itself to get even lighter as my grip cap is missing lol. Probably won't bother replacing it.

Lol, I gave mine away, it was 0.1 oz, so I HAD to do it...