Desk Jockey

WKR

- Joined

- Apr 5, 2015

- Messages

- 5,941

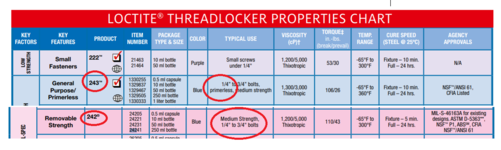

I have used loctite - blue 242 - for a while. I have had two pistol optic base plates shoot loose In the last few months. In addition to remounting those, I need to mount some scopes.

some guys at the range said I should use red loctite on the optics plates On the rails and blue on the pistol optics and scope rings Some said red all the way around On the rifle scopes.

I am degreasing with acetone and some gun scrubber using picks, paper towels and qtips.

so what say ye?

some guys at the range said I should use red loctite on the optics plates On the rails and blue on the pistol optics and scope rings Some said red all the way around On the rifle scopes.

I am degreasing with acetone and some gun scrubber using picks, paper towels and qtips.

so what say ye?