- Joined

- Oct 22, 2014

- Messages

- 14,513

There's not a specific one that I have in mind. I'm just looking for something with a friendly eyebox, lower magnifications that is drop proof/kid proof. Mil reticle. I could live with SFP but would prefer FFP. Part of my thinking is that when I dryfire with my Burris Fullfield II 2-7x35 it's easier to get behind than my SWFA 3-15. I'd like my kids to have a scope that easy to use. My hunch is that the fullfield wouldn't pass the drop test, although they are well spoken of on 24hourcampfire.

The older FFII’s were decent scopes for most lighter use. I haven’t seen enough of the new ones to say.

As for LPVO’s, pretty much-

NF ATACR and NX8

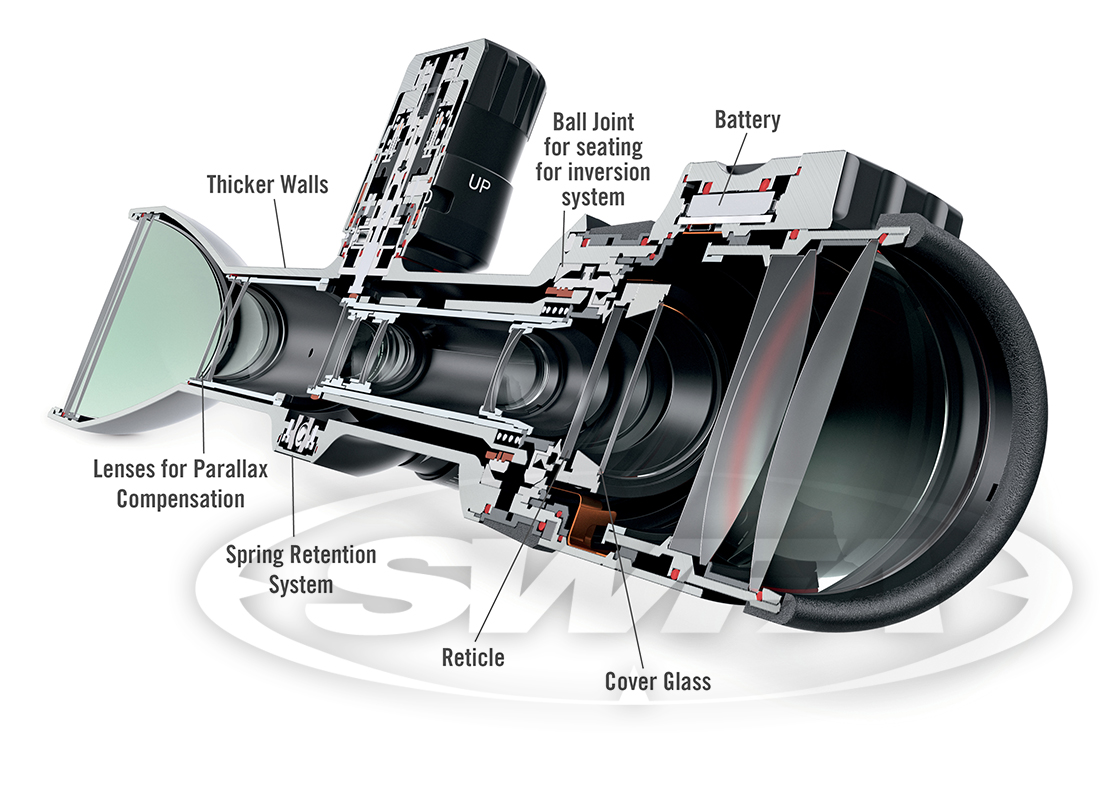

SWFA HD 1-6x and older 1-4x HD

Trijicon Credo/Accupower 1-4x, 1-6x, and 1-8x generally work well

S&B Short Dot II 1-8x