- Joined

- Sep 28, 2023

- Messages

- 2,277

I haven't zeroed it yet.Very cool, nice work, does it shoot acceptably well so far?

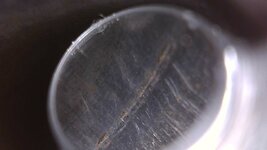

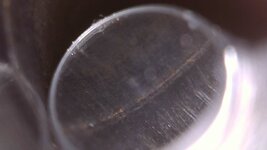

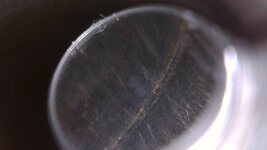

My steel is too marked up to really see what's going on.

Real tight schedule.

I'll follow up when I get the fire formed brass dialed in and the rifle zeroed.