sickles107

WKR

I have always nock tuned. Don't want to get into a debate weather it's repeatable or not, I have rolls and rolls of wax paper with sharpie and little holes showing that nock position certainly effects a paper tear.

My process has always been

1. rough tune the bow with a bare shaft

2. nock tune a batch of 4 bare shafts, find a common tear for each arrow/nock position, set them to that.

3. Fine tune the bow to those arrows to shoot a clean tear

4. Find the commen nock setting for the rest of the arrows to shoot a clean tear

5. fletch everything and go shoot

On rip tkos, I always used the spine align mark for reference, and always laughed when there was no consistency going off that. A batch of arrows that all teared clean would have the spine align mark in all different positions. And there was always 3 or 4 arrows in a batch that didn't quite tear like the others, but we're close enough. I would shoot every arrow in four positions to find the right nock setting.

Today I decided rather than reference off the spine align mark, I would reference off the seam in the carbon. Something pretty obvious I overlooked, and BAM consistent tears for each nock position. Anothing interesting find is the arrows that didn't quite tear like the others were the arrows that didn't have a straight seam, but a curved seam.

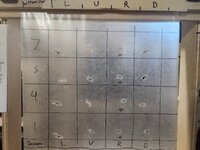

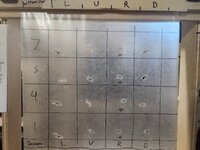

Results below, going to tune the bow to seam down (D) position as it produced the least variance in each arrow, and in the middle of each tear result.

biggest thing is now I will set all the rest of the arrows to that setting to start, and hopefully not have to shoot them all through paper in all 4 nock positions!

My process has always been

1. rough tune the bow with a bare shaft

2. nock tune a batch of 4 bare shafts, find a common tear for each arrow/nock position, set them to that.

3. Fine tune the bow to those arrows to shoot a clean tear

4. Find the commen nock setting for the rest of the arrows to shoot a clean tear

5. fletch everything and go shoot

On rip tkos, I always used the spine align mark for reference, and always laughed when there was no consistency going off that. A batch of arrows that all teared clean would have the spine align mark in all different positions. And there was always 3 or 4 arrows in a batch that didn't quite tear like the others, but we're close enough. I would shoot every arrow in four positions to find the right nock setting.

Today I decided rather than reference off the spine align mark, I would reference off the seam in the carbon. Something pretty obvious I overlooked, and BAM consistent tears for each nock position. Anothing interesting find is the arrows that didn't quite tear like the others were the arrows that didn't have a straight seam, but a curved seam.

Results below, going to tune the bow to seam down (D) position as it produced the least variance in each arrow, and in the middle of each tear result.

biggest thing is now I will set all the rest of the arrows to that setting to start, and hopefully not have to shoot them all through paper in all 4 nock positions!