Pn8hall

WKR

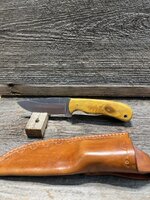

Cranked out a few Xmas presents for some pals this year. I am no expert and still have a lot to learn but very happy with how these turned out. These pics are before sharpening and final wipe down but still look sharp. AEB-L steel at 62RC with flat grind. Osage Orange from a log my buddy gave me from his stabe log for the self bow he is building, Slate gray and black G10 and Ironwood for the other.