rifletuner

WKR

- Joined

- Dec 23, 2020

- Messages

- 495

Thanks mate

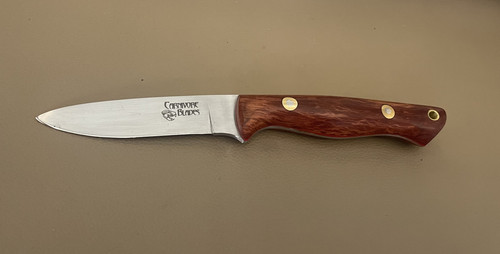

He had a lot of people look at it over the weekend, but it was still on the table Sunday afternoon. He was getting a bit disappointed it hadnt sold, when all of a sudden he got two buyers and sold two of his knives within 5 minutes.

He had a lot of people look at it over the weekend, but it was still on the table Sunday afternoon. He was getting a bit disappointed it hadnt sold, when all of a sudden he got two buyers and sold two of his knives within 5 minutes.