After years of taking dad's, my brothers, and my harvests to the processor; I bought a #22 Cabelas grinder, poly bags, and a taper 10 years ago.

My plan at the time was to grind my own burger, package my own steaks & roasts, and take my trim in to the processor for sausage / restructured jerky. I really had no idea what I was getting myself into. That very same year, a cousin asked us if we would take him on his first deer hunt. 7 days later we had 6 deer hanging. Man did we learn a ton that first year in processing, as it took us almost 4 days. That was the 4 of us and my wife helping. After that we still took meat to the processor.

(1st year for my grinder. I jumped in neck deep)

(My brother and I boning the deer out. Dad and our cousin were cleaning, final cutting, sorting, & trimming in the house)

(2nd grind on burger, because that is what we read as being SOP. So that's what we did. Doesn't work well when the meat isn't soft frozen. We now, no longer grind 2x)

Every year since we have processed no less than 6 deer and some times as many as 10. Our average is 8 deer a year, and sometimes an elk or two. Ten years later and we have grown our owned equipment. We have greatly increased our efficiency, and no longer use a processor. So far this year we have processed 7 deer in 2 days with 3 people. That was starting with whole carcasses.

(This year's buck. 46# in this tub; back straps, tender loins, and 1/2 of the round only. I boned 100.7# of meat of of this buck)

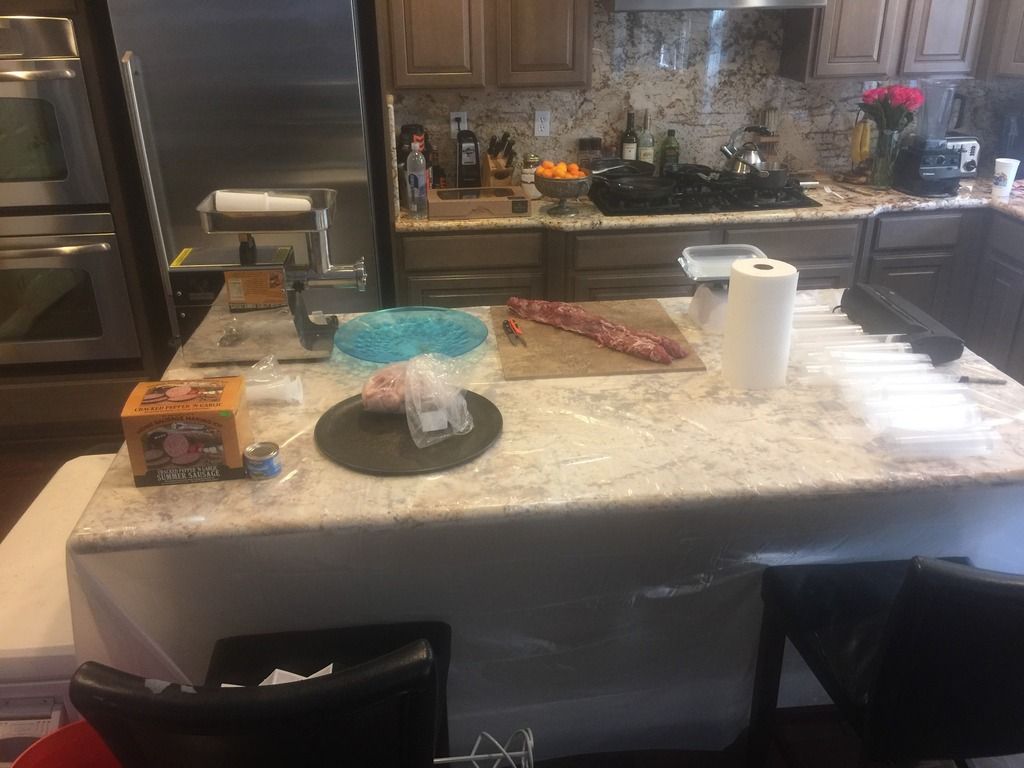

Here are couple of pictures of my processing equipment now.

Here is list of what we make in regards to deer:

Things I've learned that I think are important to know for the beginner or the guy that's just starting:

I am by no means an expert in this or pounding my chest. I've been at it long enough now that I wanted to share my experiences and some of what I have learned. I hope it is helpful.

My plan at the time was to grind my own burger, package my own steaks & roasts, and take my trim in to the processor for sausage / restructured jerky. I really had no idea what I was getting myself into. That very same year, a cousin asked us if we would take him on his first deer hunt. 7 days later we had 6 deer hanging. Man did we learn a ton that first year in processing, as it took us almost 4 days. That was the 4 of us and my wife helping. After that we still took meat to the processor.

(1st year for my grinder. I jumped in neck deep)

(My brother and I boning the deer out. Dad and our cousin were cleaning, final cutting, sorting, & trimming in the house)

(2nd grind on burger, because that is what we read as being SOP. So that's what we did. Doesn't work well when the meat isn't soft frozen. We now, no longer grind 2x)

Every year since we have processed no less than 6 deer and some times as many as 10. Our average is 8 deer a year, and sometimes an elk or two. Ten years later and we have grown our owned equipment. We have greatly increased our efficiency, and no longer use a processor. So far this year we have processed 7 deer in 2 days with 3 people. That was starting with whole carcasses.

(This year's buck. 46# in this tub; back straps, tender loins, and 1/2 of the round only. I boned 100.7# of meat of of this buck)

Here are couple of pictures of my processing equipment now.

- #22 Cabelas Grinder (10 years old this year)

- Foot pedal switch for the grinder

- 11# Sausage Stuffer

- 12mm, 16mm, 22mm, & 38mm stuffing horns

- Mundial Knives _ curved & straight blade boning _ Don't slip out of the hand, cheap, and easy to keep sharp

- LEM manual meat mixer

- Large HDPE cutting boards

- Meat hooks used when boning

- Silicone spray _ Use it on the grinder, stuffer, and associated parts. This a must when doing this kind of volume IMO

- 15" wide butcher/freezer paper stand (I buy 1000' rolls)

- Freezer paper tape holder

- Poly bag taper & cutter

- Digital scale with 300# capacity

- Cabelas 80L Commercial Dehydrator (not shown, bargain cave buy) will hold 25# of Jerky easily

- Smokers (not shown)

- Thermoworks Chef Alarm with air temp & meat probe (used for smoking and curing)

- Several meat lugs (actually restaurant busboy lugs) fit in my coolers and freezers

- Fatigue mats for standing on. A guy's back and legs appreciate it.

Here is list of what we make in regards to deer:

- Burger

- Roasts

- Steaks

- Whole Muscle Jerky

- Snack Sticks

- Summer Sausage

- Fresh Sausage

- Italian Sausage

- Chorizo

Things I've learned that I think are important to know for the beginner or the guy that's just starting:

- When dealing with whole carcasses, learn how the animal is put together so you can bone them quickly and efficiently.

- A good Grinder is paramount, and get the biggest you can afford with a foot pedal switch.

- Stuffing poly bags with burger off a grinder is ok, but it is horribly slow IMO if you are doing more than 25#

- If you are going to make stuffed sausages, sticks, or restructured jerky at higher volumes; then buy a stuffer.

- The dedicated stuffer was a game changer for us ...I can't say it enough...

- Take your time and make sure your meat is clean and trimmed accordingly! Attention to detail makes for a good product.

- Sort your meat by keeping large muscles and meat with lots of connective tissue separated. This organization allows you to plan what you are going to make in product. It also keeps your dinner guests from having a bad experience

- Due to our pickiness on the cleanliness and sorting of meat, I only grind one time for burger now.

- I will still grind twice for snack sticks and summer sausage. Soft freeze the meat between grinds

- When making whole muscle jerky use the biggest pieces of meat that you can. Cut your pieces across the grain.

- A slicing knife is wonderful for cutting whole muscle jerky slices. I have an 18" long one

- Always work with soft frozen meat when possible. The only time I don't is when mixing meat seasonings for sausages, and then it is very cold.

- If using/adding fat for sausages (I prefer pork fat), keep it frozen until you need it. If it warms up much it is miserable to grind; like working with snot.

- Keep your grinder parts ice cold. This includes the plates, knives, auger, throat, throat nut, and meat tray.

- Keep your grinder plates & knives paired up, because they will wear into each other.

- Keep your grinder plates flat and sharp. I do this every couple of years.

- Use silicone spray prior to starting, during, prior to storing your equipment. It makes for easier processing & cleaning.

- Butcher / Freezer Paper works just fine. Buy the heavy duty paper, wrap it tight, and keep your freezer organized.

I am by no means an expert in this or pounding my chest. I've been at it long enough now that I wanted to share my experiences and some of what I have learned. I hope it is helpful.

Last edited: