TaperPin

WKR

- Joined

- Jul 12, 2023

- Messages

- 6,317

Great job with your progress!More progress.

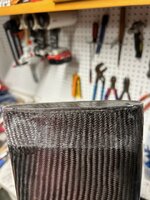

The CF sleeve that I bought is 4” diameter, which shrinks if you pull longitudinally and expands if you open it up. I thought it was an awesome idea. I’m sure it works great for straight projects, but is not as great as I expected for a stock. The height at the butt pad is 5.75”, with the front of the forend at around 2”. These changes, combined with the two curves at the grip and the extra thickness from the cheek piece makes it hard to get the sleeve to conform perfectly.

So I decided to work in halves, overlapping at the grip which needs extra reinforcement anyway. I vacuum bagged the butt side first. 2 layers of CF, then peel ply and breather, and into the large vacuum bag from Harbor Freight. It worked okay, but I ran out of time quickly (I hoped to get 3 layers down), and ended up with quite a few ripples. The stock was at 6.1 oz before, and 10.0 oz after.

View attachment 594130

View attachment 594129View attachment 594131

View attachment 594134

Thankfully, the ripples and imperfections cleaned up pretty easily, and I was down to 9.6 oz. But I had filed all the way through to the foam core in two small spots. I think 2 layers is probably strong enough, but my surface was rough.

Then I vacuum bagged the forend side, with similar results. It worked okay, but ran out of time way too fast, had trouble conforming as well as I wanted, and the end result seemed a bit thin on resin. We are at 13.3 oz after cleaning it up some.

View attachment 594143

View attachment 594144

View attachment 594145

I decided for the 3rd layer that I was planning on and already had the material for I would do another wet layup, with no vacuum bagging. With my beginner skills and equipment, I can get a better surface finish without vacuum bagging, as well as seemingly better resin distribution and CF placement. Go with what works.

View attachment 594147

I just laid it up tonight, so no results yet. I cut the sleeve lengthwise to essentially make a normal CF sheet. I’m definitely learning a ton, and don’t think I’ll use sleeve material again. This was the first layup (besides the simple rectangle patches early on) that I’m happy with right away.

Edit: wow, this post turned out crazy long, I’ll try to break it up next time

Just like with fiberglass bodywork on a car, the absolute worst thing that can possibly happen is you grind out a spot and redo it until it’s acceptable, so don’t let little snags along the way slow you down.