After the initial attempt (with the failed bedding) I decided to do some changes. The first rifle I was bulding a carbon fiber stock for was a Blaser R8 straight pull. The action on that rifle somewhat special, as the barrel is fixed to a small "chassis", and the bolt locks directly to the barrel.

View attachment 668417

I found it hard to bed this "action" to the stock, especially making the sidewalls stiff enough.

View attachment 668419

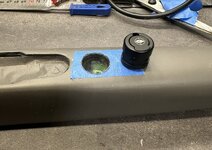

A solution and work-around for me was to sacrifice the original stock, which was kinda rough, worn down and ugly anyway. I cut out the section that holds on to the action, and joined it to the carbon fiber reinforced foam core. The foam (white) I used on this stock is called Bonocell. I would not recommend it, as it is a bit to soft. I later switched to Divinycell PVC (green) which is a whole different league.

After I glued together the foam and the stock middle section, I began take two on the design:

View attachment 668434

View attachment 668435

When I was happy with the stock design, it was time for carbon fiber cloth. I brushed resin on the foam core, waited a couple of hours for it to become sticky, and then wrapped the cloth on the core. This was then wrapped in peel ply and breather, before everyting got tucked into a vacuum bag and sealed off.

View attachment 668445

I wasn't sold on the grip area, so this needed some modifications (excuse the mess):

View attachment 668446

After I was done with the adjustments, it got a couple more layers of carbon fiber:

View attachment 668452

I gave this stock a finish of epoxy top coat, some sponge camo and matte clear coat. I probably could have / should have done some more work on the finish, removing some dings and scars, but I was to eager to finish it up and go shooting. The grip areas was done by mixing epoxy and blaster sand.

View attachment 668453

Here it is dressed up with a Krieger 280AI barrel:

View attachment 668454