I'm curious if there is any published information available as to the Max RPM a given bullet has to kept under before disintegration will start to occur? Do the bullet manufacturers have this info? Or is this something found through trial and error?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bullet Disintegration

- Thread starter jfjohn77

- Start date

WKR

WKR

- Joined

- Jun 14, 2019

- Messages

- 2,214

there are so many variables that come into play (groove type and quantity, bullet construction, jacket thickness, twist, etc....) that it would be hard to quantify.

I havent found a controlled study with a test barrel and projectile but would be interested to read one if someone has done it. But I tend to think its like you say, trail and error with any given bullet/barrel

I havent found a controlled study with a test barrel and projectile but would be interested to read one if someone has done it. But I tend to think its like you say, trail and error with any given bullet/barrel

This issue comes up a lot with the new 8.6 Blackout round which has an unusually fast twist rate of 1:3. I have one. With those guns, it is recommended that only monolithic copper bullets be shot in supersonic loads, as normal cup and core and lesser bullets will spin apart once they leave the muzzle which will wreck a suppressor as well as not even make it to the target. With subsonic loads, we are ok to use normal match bullets for targets. It's a pretty simple conversion to get RPMs from your MV and barrel twist. As WKR said, there's a lot of variables that would come into play, but we at least know there is a definite point between a bullet traveling 1000 fps and under in a 1:3 twist, and a bullet traveling 1800+ in a 1:3 twist where bullets definitely blow up (and it's probably closer to the subsonic end of that range)

roadrunner

WKR

For the bullet to "fly apart", the outward forces would need to exceed the inward forces.

These two forces are centripetal and centrifugal. Theoretically, the bullet begins to lose rpm the moment it leaves the barrel. The bullet in the barrel is in equilibrium: it doesn't collapse under pressure and doesn't come out in shards.

Material defects or a structure that would jack with moments of inertia in the core of the bullet could contribute to something like that.

These two forces are centripetal and centrifugal. Theoretically, the bullet begins to lose rpm the moment it leaves the barrel. The bullet in the barrel is in equilibrium: it doesn't collapse under pressure and doesn't come out in shards.

Material defects or a structure that would jack with moments of inertia in the core of the bullet could contribute to something like that.

wind gypsy

"DADDY"

- Joined

- Dec 30, 2014

- Messages

- 11,591

Common recommendation is to keep them under 300k rpms but as has been stated already, that’s just one contributing factor to jacket failure.

WKR

WKR

- Joined

- Jun 14, 2019

- Messages

- 2,214

Yeah I have always heard and even adhered to the 300k, but where is that number coming from?Common recommendation is to keep them under 300k rpms but as has been stated already, that’s just one contributing factor to jacket failure.

Sometimes I wonder if its a little like the whole 1500 ft lbs of k/e.

rayporter

WKR

one factor is the number of shots on the barrel.

i have had 105gr and 88 gr bullets 6mm leave a blue cloud consistently and by the same token a 55 gr 6mm and a 68 gr 6mm stand a lot of speed in an 8 tw barrel and never disintegrate.

about the time you name a number you will find an exception to the rule.

i have had 105gr and 88 gr bullets 6mm leave a blue cloud consistently and by the same token a 55 gr 6mm and a 68 gr 6mm stand a lot of speed in an 8 tw barrel and never disintegrate.

about the time you name a number you will find an exception to the rule.

Twist and velocity is what most people think is the end all but not that simple. As someone mentioned, grooves have big impact and believe it or not barrel length plays a role. Rub your palm real quickly across your carpet for 6-8” and then do the same for 3’ … you ll experience the friction a long barrel does to a jacket regardless of speed differences. I did some reading on this topic a few yrs back and one individual who seemed quite knowledgeable stated that friction contributes to bullet blowups as much as velocity !?!?

I do know when we were blowing up 108 gr Eldms out of a wildcat 6-280AI cartridge with 30”barrels and 3 groove Liljas (3500 fps) and then shot the same load in a 30” six groove barrel ( don’t remember manufacturer) we got every bullet to stay together to our 300 yard target!

I do know when we were blowing up 108 gr Eldms out of a wildcat 6-280AI cartridge with 30”barrels and 3 groove Liljas (3500 fps) and then shot the same load in a 30” six groove barrel ( don’t remember manufacturer) we got every bullet to stay together to our 300 yard target!

Hornady tech told me 300k rpm is the point traditional cup and core bullets start coming apart in harsh barrel conditions.Yeah I have always heard and even adhered to the 300k, but where is that number coming from?

Sometimes I wonder if its a little like the whole 1500 ft lbs of k/e.

Byrdman

Lil-Rokslider

- Joined

- Dec 23, 2023

- Messages

- 105

That number is coming from/recomended by bullet manufacturer. I questioned Hornady about it for a .277 vmax bullet in a 1:7.5 twist barrel and under 300,000rpm is what they recommend. Doesn’t mean it would automatically fly apart at 300,001rpm as there are other variables. Just a guideline. If you have a certain bullet you are looking at don’t be afraid to contact the bullet manufacturer for their adviceYeah I have always heard and even adhered to the 300k, but where is that number coming from?

Sometimes I wonder if its a little like the whole 1500 ft lbs of k/e.

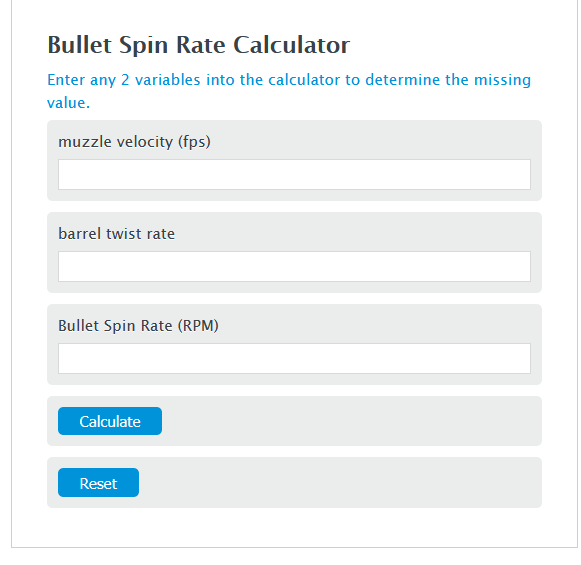

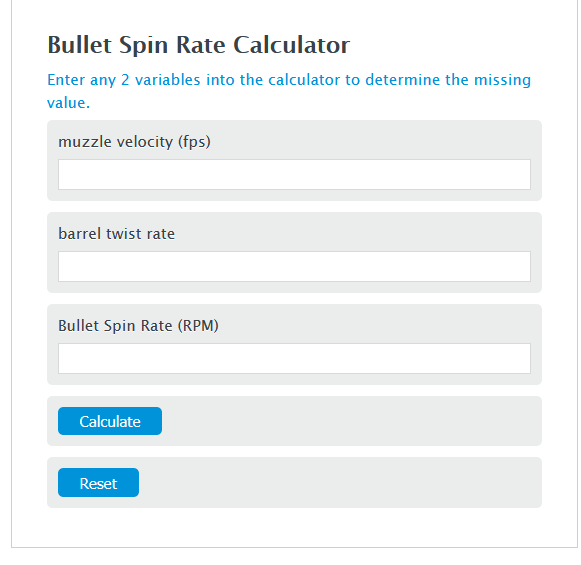

This is where all this becomes confusing and contradictive. I have an article published on loaddata.com dated Sep 13 2022, that gives his recorded load data with velocities from a 1:7 twist bbl using 5 different bullets and 9 different loads per bullet. I used a Bullet Spin Rate Calculator for fastest velocity of each bullet and found the rates between 332229 rpm for the 90 gr Berger and 371931 for the 69 gr RMR. Now he published group sizes for each load, so the bullets obviously made it to the target, and now I'm left scratching my head.

calculator.academy

calculator.academy

.22 Creedmoor Loads Using Peterson Cartridge Small Rifle Primer Brass | Load Data Article

The .22 Creedmoor is nothing more than the 6.5mm or 6mm Creedmoor necked down to accept .224 bullets without any further changes (necks may require turning or reaming to ensure proper chamber fit/bullet release). The trim-to length is 1.91 inches, like the 6mm Creedmoor. The .22 Creedmoor makes...

loaddata.com

Bullet Spin Rate Calculator - Calculator Academy

Source This Page Share This Page Close Enter the muzzle velocity (fps) and the barrel twist rate into the Calculator. The calculator will evaluate the

calculator.academy

calculator.academy

Last edited:

Similar threads

Featured Video

Latest Articles

- Hoyt RX-9 Ultra Review

- Hunting Vampire Bucks & Building an Optics Kit

- Darton Sequel ST2 35 Review

- TT#61 Gear and Skills for Success with Aron Snyder

- Vortex Viper Shotgun Enclosed Micro Red Dot Review

- Howard’s Total Vise Legacy Bow Press

- Tcams, Point Creep, Scouting, & The Hunt Source Podcast

- TT#60 Henry Ferguson Killing Big Muley’s with a Bow

- Zeiss SFL 12×50 Review

- Swarovski EL Range 12×42 TA Binocular Review