deertrout

Lil-Rokslider

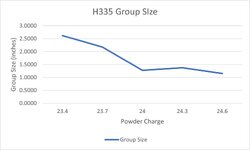

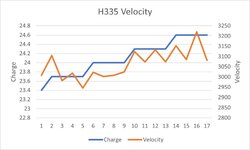

Finally got some better weather so I hit the local gravel pit after work last night. Was very rewarding to see all the bullets I made work as intended. Got a couple charge weights (24.0gr and 24.3gr) that performed really well so I'm gonna load some more of those up to do a head to head with a larger sample size. The 24gr was really promising, had a SD of 11.3 but the 24.3gr group was about 100fps faster and just as precise with a SD of 31.4 which I thought wasnt too bad. 24.6gr shot well, too, but I saw some stretching of the brass near the case head. I'm pretty sure they're ok but I don't have any experience so I'm gonna back away from there for my next round of testing. Doesn't make sense to me to be so hard on the brass if I'm not getting anything extra out of it.

This reloading stuff is fun!

Last edited: