Converted one of my ultralight gassers over to gas-less. Rifle weight right around 3.5lbs

Modified slick slide upper and KAK 7075 bcg with custom charge handle (11.2oz)

Custom captured spring setup to hold bolt closed. 1.3oz

Milspec lower with custom machining: larue mbt-2s trigger and standard milspec lpk

Custom barrel nut and 10” carbon handguard (3.2oz total)

Shaw portless barrel.

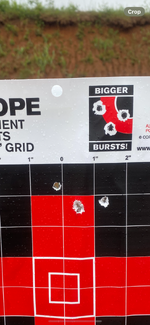

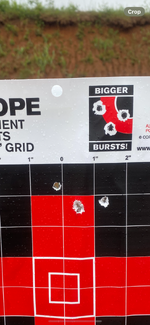

Custom carbon stock using Ace ultralight tube. Looks like an A1 tube but carbine length. Butt pad is 3D printed foam with nice grip and a little cushion. I wanted something that was comfortable and has good cheek weld. I figure if I am building it, I want it to look nice and function well. My handguard is a little longer and a little larger. As an engineer I cringe at 1.350” diameter aluminum barrel nuts. Especially the cheap ones. This one is machined from 7075. Outer diameter of the carbon tube is 1.575” which is closer to standard ar handguards. I have few things planned to drop a few ounces but pretty happy with it. I did not want to run any plastic lowers or anything like that. I may change the grip out to something larger like my B5 P-22 at a .5oz gain but a 3D printed trigger spacer is working for now. Using a Sightron Big Sky 3.5-10x42 for load development so far but may give a 5x prism a try. Best 5 shot group so far was right around 1moa. Only ran about 25 through it so far so should tighten up. Sitting at 4.8lbs with stainless mag and all as is now. Prism and a few other mods I have in mind would put it right around 4lbs. Not bad for all metal receivers and full length bcg and spring setup. I have a new spring design that fits inside the upper receiver only that I will machine up and test soon.

View attachment 876796

View attachment 876797

View attachment 876798

View attachment 876801

View attachment 876805