Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Torque value tikka

- Thread starter speck

- Start date

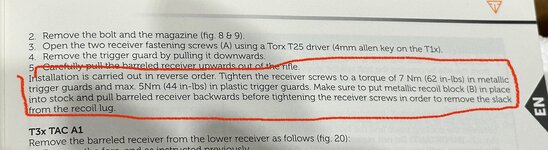

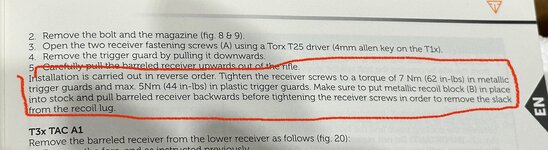

Not an expert, but the tikka manual states that you should use no more than the equivalent of 45 in/lb on the plastic trigger guards, 62inlb in metal (ctr) trigger guards. Use at least 45in/lb, and maybe go up from there carefully, probably dont go higher than 65. Id for sure use 60+ in a metal guard.

The 2 issues I have heard of using more torque are 1) pulling screw heads through the plastic bottom-metal on the lite versions (non-issue in a ctr) and 2) bending or compressing the plastic so it is not a consistent bedding surface and allows movement (bad). My impression is MOST people dont have these issues. Some people have bedded or even pillared the plastic stocks in order to get a stronger, less compressible surface, although you have to be careful to make sure whatever used adheres to the plastic. Before moving to an aftermarket stock on mine I always used 45in/lb with success not having known any better. A krg bravo can be had relatively inexpensively and “fits” on a ctr like beer goes with pizza, in which case 65in/lb.

The 2 issues I have heard of using more torque are 1) pulling screw heads through the plastic bottom-metal on the lite versions (non-issue in a ctr) and 2) bending or compressing the plastic so it is not a consistent bedding surface and allows movement (bad). My impression is MOST people dont have these issues. Some people have bedded or even pillared the plastic stocks in order to get a stronger, less compressible surface, although you have to be careful to make sure whatever used adheres to the plastic. Before moving to an aftermarket stock on mine I always used 45in/lb with success not having known any better. A krg bravo can be had relatively inexpensively and “fits” on a ctr like beer goes with pizza, in which case 65in/lb.

+1 what @Macintosh said. I torque the action screws with the stock bottom "metal" plastic a little over the 45 in/lb recommendation to 50-60 in/lbs.

There have been reports on this forum with a couple of issues and things to be aware of when changing trigger springs or re-installing the trigger to the action:

The OEM trigger spring is more reliable and safer than aftermarket options. Here's an example:

I've decided to leave good enough alone and just backed out the trigger pull adjustment screw all the way out until it contacts the screw that holds the trigger to the action. This has resulted in 2.25-2.5 lb triggers on a few Tikkas and I've been totally content with that.

Also, make sure to loctite/paint pen the threads on the trigger to action screw and torque to 55-65 in/lbs to avoid having issues. Tikka triggers from the factory shouldn't come loose, always a good idea to verify, but now that you've removed it, make sure that trigger is on there good and tight:

There have been reports on this forum with a couple of issues and things to be aware of when changing trigger springs or re-installing the trigger to the action:

The OEM trigger spring is more reliable and safer than aftermarket options. Here's an example:

Posting this so more people might see it and consider leaving the factory spring alone.

I just got back from the S2H Winter course where I shot a Tikka RSS 223. I like a light trigger so I chose to try replacing the factory trigger spring with a lighter trigger spring.

On day 6 I had a accidental discharge when I closed the bolt. Fortunately it was rnd 3 on target during an exercise. Running the bolt hard and fast I believe exaggerates the failure earlier than if it is run less aggressively.

Form confirmed failure by running the bolt 15-20 times and had another failure, rifle unloaded...

I just got back from the S2H Winter course where I shot a Tikka RSS 223. I like a light trigger so I chose to try replacing the factory trigger spring with a lighter trigger spring.

On day 6 I had a accidental discharge when I closed the bolt. Fortunately it was rnd 3 on target during an exercise. Running the bolt hard and fast I believe exaggerates the failure earlier than if it is run less aggressively.

Form confirmed failure by running the bolt 15-20 times and had another failure, rifle unloaded...

- longrangelead

- Replies: 89

- Forum: Firearms

I've decided to leave good enough alone and just backed out the trigger pull adjustment screw all the way out until it contacts the screw that holds the trigger to the action. This has resulted in 2.25-2.5 lb triggers on a few Tikkas and I've been totally content with that.

Also, make sure to loctite/paint pen the threads on the trigger to action screw and torque to 55-65 in/lbs to avoid having issues. Tikka triggers from the factory shouldn't come loose, always a good idea to verify, but now that you've removed it, make sure that trigger is on there good and tight:

The other day I was out in the shop messing around and decided to pick up one of my Tikka's and practice manipulating the bolt rapidly. After a time or two something didn’t feel correct. It was releasing the firing pin on closing. Luckily it was on an empty chamber.

After a close inspection and tear down, I found the problem to be the Allen screw holding the trigger assembly to the action was loose. Upon further examination, it took roughly 1/4 of a turn from tight to allow enough slop in the trigger assembly for the seer to release the firing pin. I also noticed this screw does not have...

After a close inspection and tear down, I found the problem to be the Allen screw holding the trigger assembly to the action was loose. Upon further examination, it took roughly 1/4 of a turn from tight to allow enough slop in the trigger assembly for the seer to release the firing pin. I also noticed this screw does not have...

You can get little washers to shim the back of the trigger guard holes to support the metal embedded in the plastic bottom metal (just that part, not under the plastic). So you’re tightening onto mental vs potentially bending the embedded metal.

Pharmseller

WKR

45 in/lbs for mine.

P

P

Please consider putting your factory trigger spring back in. Regardless of that, please torque and thread lock the hell out of the large trigger attachment bolt. Those loosening over time is the primary cause of Tikka NDs. You can read more in the threads posted above.I recently purchased a Tikka T3X CTR. I removed the action and replace the trigger spring. What torque value do you tikka experts recommend when replacing the action to the stock?

Anything from 55-65 inLB is plenty for your action screws, just witness mark them.

-J

Similar threads

- Replies

- 8

- Views

- 971

Featured Video

Latest Articles

- Banning Hunting Technology in Idaho?

- Best Gear of the year Rokslide staff edition 2025 Article

- Hunting Gear: Insights from Western Hunting Expo

- Black Diamond Alpine Start Insulated Hoody Review

- Tenacity Firearms with Andrew Whitney

- The Thrill of Moose Hunting with Henry Ferguson

- Final Rise Upland Hand Muff Review

- Kodiak Deer Hunt Round II

- Killing a Timber Giant

- Titanium Suppressor Shootout