Hill Difficulty

WKR

- Joined

- Sep 30, 2019

- Messages

- 1,126

Here's a little 700 insight since posting @ #6574. Hoping other 700 buyers had better fitting.

Since receiving the stock I have noticed and remedied the following:

Feedback + comments:

Note: If anyone has a 700 SA with inlet issues that are too prohibitive, let me know and I might buy.

Since receiving the stock I have noticed and remedied the following:

- tang inlet too short - fix: cut with a Dremel

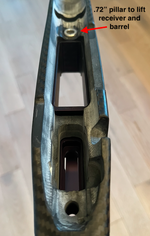

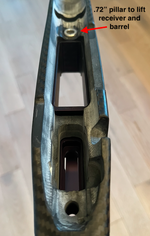

- height at front action screw way too low - fix: bed a .72" front aluminum pillar to raise receiver height

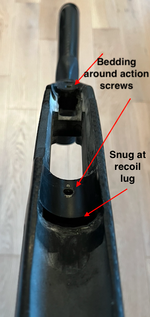

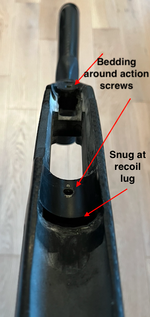

- entire barrel in front of lug laid in the barrel channel - fix: pillar and epoxy bed around rear tang + area between mag well and recoil lug

- back of recoil lug did not seat in lug well (see 1/32" space) - fix: epoxy bedding

Feedback + comments:

- Very pleased with the stock now that all the inletting issues are resolved - it's an excellent stock so big thanks to everyone involved with bringing this together

- Stock satisfies my interest in a Clymer (Poor Man's Clymer?), $500ish is the right price considering the inletting errors/time and trouble required to remedy

- FWIW, would pay more if a true drop-in that could be used interchangeably with other barreled actions

- Hoping UM and Stockys get the CS (tell the truth, always) and production bugs worked out before producing more 700 inlets

- A compact version with 4" less fore-end length would be cool, but that's personal preference

Note: If anyone has a 700 SA with inlet issues that are too prohibitive, let me know and I might buy.