deer_hunter132

FNG

- Joined

- Nov 21, 2023

- Messages

- 90

Dad has a browning A bolt 7 rem mag with the boss "brake".

Last shooting session we determined the Swarovski was bad.

Hes got his old pentax on it that it sported years ago.

We were using a old metal caldwell type sled. The recoil was a bit much on his shoulder after a bit.

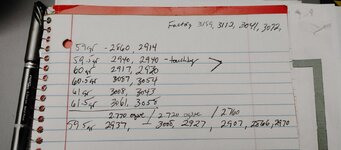

Yesterday we started testing hand loads doing a powder ladder of .5gr and seated as long as the magazine would allow, which was about .02 from jam.

Decided to use my tripid. The first 12 shot just as well as we could expect from a tripod and our ability. Shot a couple factory hornady sst loads of the same projectile and they grouped right in line with the others.

Pulled the gun from the tripod to check out the mag spring (weak).

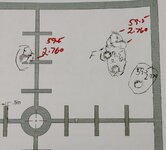

Loaded another 3 at the 59.5gr that did well in the powder test. 1 (3 total) at 2.770 ogive to base. Back in the tripod. Went 2" right and .5" low compared to the first two. Tried 2.760 and 2.720 seating depth at the same charge and two factory loads. The groups are 3" apart left/right. Im wondering if i tightened down the bipod gimble and we were torquing the stock into the barrel to get it on target causing the shift.

I say all of that to ask this; is there a design a welder can duplicate that keeps us from imparting force into the stock/barrel while putting the gun on target and steady and absorbing some recoil?

Last shooting session we determined the Swarovski was bad.

Hes got his old pentax on it that it sported years ago.

We were using a old metal caldwell type sled. The recoil was a bit much on his shoulder after a bit.

Yesterday we started testing hand loads doing a powder ladder of .5gr and seated as long as the magazine would allow, which was about .02 from jam.

Decided to use my tripid. The first 12 shot just as well as we could expect from a tripod and our ability. Shot a couple factory hornady sst loads of the same projectile and they grouped right in line with the others.

Pulled the gun from the tripod to check out the mag spring (weak).

Loaded another 3 at the 59.5gr that did well in the powder test. 1 (3 total) at 2.770 ogive to base. Back in the tripod. Went 2" right and .5" low compared to the first two. Tried 2.760 and 2.720 seating depth at the same charge and two factory loads. The groups are 3" apart left/right. Im wondering if i tightened down the bipod gimble and we were torquing the stock into the barrel to get it on target causing the shift.

I say all of that to ask this; is there a design a welder can duplicate that keeps us from imparting force into the stock/barrel while putting the gun on target and steady and absorbing some recoil?