Buffalo-Jo

FNG

- Joined

- Jun 1, 2024

- Messages

- 93

I picked up a lone peak fuzion medium action that I intend to build a 6.5PRC on. I ordered a top teir barrel from a pretty reputable barrel supplier which also cuts them to pre-fit specifications. Until resolved, will remain nameless, just looking for additional insights.

I got the barrel last week and decided to make sure that everything threaded up together before actually fitting it up. I'm still waiting on other components so wasn't in a hurry to get everything formally fit up. I was able to get the threads to start about 1 rotation before they were locked up solid. I pulled it apart, cleaned and greased the threads more meticulously and still locked up at ~1 rotation. I didn't have the barrel in a vice and was only threading by hand so no damage was done to threads.

I called the supplier and they said that Lone Peak was known to cut the threads in the action shallower than what they should.

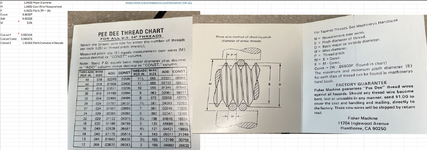

Here are the measurements I pulled on the action and the barrel

So a few questions for my fellow roksliders

I got the barrel last week and decided to make sure that everything threaded up together before actually fitting it up. I'm still waiting on other components so wasn't in a hurry to get everything formally fit up. I was able to get the threads to start about 1 rotation before they were locked up solid. I pulled it apart, cleaned and greased the threads more meticulously and still locked up at ~1 rotation. I didn't have the barrel in a vice and was only threading by hand so no damage was done to threads.

I called the supplier and they said that Lone Peak was known to cut the threads in the action shallower than what they should.

Here are the measurements I pulled on the action and the barrel

- Action inner diameter (ID) - 0.996" - would be the peaks of the internal threads

- Barrel shoulder - 0.979"

- Barrel Tenon outside diameter (OD) - 1.062" - measured using the wide part of calipers

- Tenon Thread valley - 1.011" - depends on how sharp my caliper beveled points are and slight angle to calipers to stay in the same thread path

So a few questions for my fellow roksliders

- Is this an accurate enough way to access the problem so I can figure out if I need to get the barrel worked on or the action?

- Has anyone else ran into this issue with lone peak actions?