NorthIdahoDude

Lil-Rokslider

- Joined

- Aug 29, 2022

- Messages

- 161

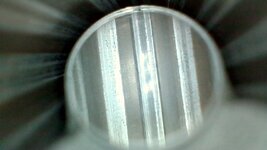

So, I have a Remington 700 that I got from a friend that I'm kind of sentimental about. The gun originally had a sewer pipe for a bore (rust, rust, more rust), and was about a 3.5 to 4 MOA shooter, which wasn't not shocking - it was more shocking that a bullet would go through the barrel and not get stuck in the rust!

So I swapped out the barrel for a Criterion Remage (30-06) from Northland. Since it's just a hunting gun and anything around 1 MOA was going to make me happy, I had the smith forgo doing any work on the action other than swapping the barrel and headspacing, and he seemed to agree with my thought that since I am not trying to build a 1/4 MOA bench gun, just a MOA-ish hunting rifle, that it should be fine to go that route.

Long story short - we made some very solid improvements over the 3.5 MOA sewer pipe, but I'm still struggling to get a load that'll come in under 1.75MOA consistently, and I'm wondering if the blame is more the barrel or if it's my bad for not having the action trued up/blueprinted/whatever you call it.

And before everyone asks, yes, the action is bedded into the stock, yes, the scope bases and rings are tight, yes the scope is one I've verified good on other rifles - so while it's possible I'm missing something minor, I don't think I'm missing anything major enough to make a 1MOA a 2MOA gun. Have tried AccuBond's (150, 165, and 180s), ELD-X's (178's), 168 SMK's, IMR and H 4350, N555 (the best of all the things I tried), N160, Hunter, Varget (with the 150s), and Staball 6.5 - so I'm feeling like I've covered the 'known good components' bit pretty good. And I load for several other rifles that shoot great, so I'm feeling like my loading process/techniques are reasonable.

Discuss and vote, please and thanks.

EDIT TO ADD: when I say "come in under 1.75 MOA" - I mean 10 rounds or more, if I was just knocking out 3 shot groups, this one shoots around 1 MOA 3 out of 5 times ish.

So I swapped out the barrel for a Criterion Remage (30-06) from Northland. Since it's just a hunting gun and anything around 1 MOA was going to make me happy, I had the smith forgo doing any work on the action other than swapping the barrel and headspacing, and he seemed to agree with my thought that since I am not trying to build a 1/4 MOA bench gun, just a MOA-ish hunting rifle, that it should be fine to go that route.

Long story short - we made some very solid improvements over the 3.5 MOA sewer pipe, but I'm still struggling to get a load that'll come in under 1.75MOA consistently, and I'm wondering if the blame is more the barrel or if it's my bad for not having the action trued up/blueprinted/whatever you call it.

And before everyone asks, yes, the action is bedded into the stock, yes, the scope bases and rings are tight, yes the scope is one I've verified good on other rifles - so while it's possible I'm missing something minor, I don't think I'm missing anything major enough to make a 1MOA a 2MOA gun. Have tried AccuBond's (150, 165, and 180s), ELD-X's (178's), 168 SMK's, IMR and H 4350, N555 (the best of all the things I tried), N160, Hunter, Varget (with the 150s), and Staball 6.5 - so I'm feeling like I've covered the 'known good components' bit pretty good. And I load for several other rifles that shoot great, so I'm feeling like my loading process/techniques are reasonable.

Discuss and vote, please and thanks.

EDIT TO ADD: when I say "come in under 1.75 MOA" - I mean 10 rounds or more, if I was just knocking out 3 shot groups, this one shoots around 1 MOA 3 out of 5 times ish.