Step 4: fixing the stock geometry. This is where what I do differs significantly from what I've seen anyone else try. The objective is to achieve negative drop at the heel, negative comb angle, keep the factory butt pad, and be able to remove the bolt with the action fully torqued.

First, mark the location where the bolt is furthest back when removing or reinstalling it from the action. Mess this up and you're in for a lot of sanding, or you have to remove screws to remove the bolt. I used tape and cardboard:

View attachment 587137

Now, remove the action and find something you can reference off the nice bedding job you did to that same point. This big nail and a few wraps of electrical tape worked for me.

View attachment 587138

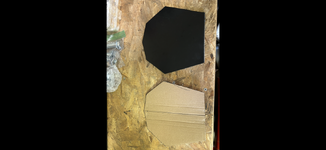

Now that we know what has to stay clear, it's time to cut.

First cut, mitre saw at 0 degrees. You might want to go a bit further back than I did here, depends on how much you value a continuous top angle vs really wanting the flattest possible bottom.

View attachment 587139

After that, set a slight angle on the saw, set aside the butt pad piece, and cut again, with the cut starting from the bottom edge of the first cut. I used 5 degrees.

View attachment 587141

View attachment 587140

After making the cuts, it's time to start fitting stuff back together, making sure to leave room for the bolt to be removed, while achieving a negative drop at the heel. That 5 degree angle already guaranteed negative comb angle. Using some tape can help you out, and the seems work well for making sure nothing is twisted.

View attachment 587142

The last geometry fix is to flatten the bottom. Perfectly flat is best, but any amount flatter is an improvement. Pick out a stiff carbon arrow you don't like (250 spine rampage), and find a drill bit a smidge larger. Drill a divot forwards to make a pocket to hold the arrow piece at the bottom back of the pistol grip.

View attachment 587143

Then, at the vestigial sling stud screw hole, cut a notch with a Dremel cut off wheel, and make a channel so that arrow shaft can lay in flush.

Midway

View attachment 587148

Not quite

View attachment 587149

Good

View attachment 587150