Choupique

WKR

- Joined

- Oct 2, 2022

- Messages

- 1,066

How the hell do you check the thing? I don't have a calibrated bullet launcher

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Shoot long and check data.How the hell do you check the thing? I don't have a calibrated bullet launcher

With another chrono. Run the bullet thru both in line.How the hell do you check the thing? I don't have a calibrated bullet launcher

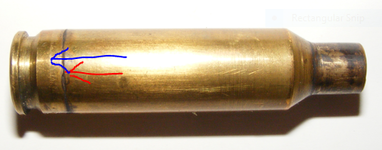

Headspace is easy to check with scotch tape

I reload all my hunting ammo and the trick to it is that I always make sure every round will load/chamber perfectly before the ammo goes to the field. You are correct, it is not something you want to learn in the field. So, I check them all before they get to go.I always full length size my hunting loads. Having case/cartridge problems on a serious hunt is the last thing I want to deal with .

Or a Sharpie.Copy. Will do this next time I get the rifle out.

I've been reloading metallic cartridges since 1990. I shoot primarily 308 and 223. My end of life failure mode is split case necks. I opened a box of 50 and banged out 30 or 40 one evening shooting milk jugs. About 1/3 of them split. Zero of the missed or did anything stupid.I've never had a case failure, but I'm still pretty new to reloading. What should a guy look for to determine when brass is shot (pardon the pun)? Loose primer pockets are one indicator I've heard of, but what other signs should we be looking for when deciding what brass can no longer be sized/reloaded? I've got 3 firings on some .308 brass that I've necked down to 7-08, and so far I don't see anything suspicious. Thank you in advance!

Yes, loose primer pockets is one indicator. If they start out being tight with new cases, it's an indication of over pressure loads.I've never had a case failure, but I'm still pretty new to reloading. What should a guy look for to determine when brass is shot (pardon the pun)? Loose primer pockets are one indicator I've heard of, but what other signs should we be looking for when deciding what brass can no longer be sized/reloaded? I've got 3 firings on some .308 brass that I've necked down to 7-08, and so far I don't see anything suspicious. Thank you in advance!