- Banned

- #21

If you have some your old fired brass, find the shoulder length datum of those fired cases wirh a 400 or 420 bump gauge(primers removed). You fired/sized adg brass sized should be 0025-003, shorter than that if the old brass was fully formed to the chamber.

If you were using Hornady, it's very soft in the web area, and your dies were likely sizing it adequately at the base. ADG brass is very hard in the web, and requires a pretty tight fitting die to get that area sized, if it's not getting sized enough, this is where "clickers" come from upon primary extraction opening the bolt. You may need tighter dies with the ADG, rcbs matchmaster and bullet central micron are the tightest off the shelf dies I've going for saum and prc cases.

I've run both Hornady and ADG 65saum brass. The newer HDY stuff is actually pretty decent, but doesn't handle pressure as well as ADG. I personally had no issues swapping direct loads from HDY to ADG.

Your lot of ADG brass may have thicker necks than Hornady mine did. I ended up turning the necks. Less neck clearance will increase pressure as well. Can you easily slide a case into a fired case neck? If you're having to force it in, your necks are tight.

What this sounds like is oversized brass to me tho. The above post about excessive bump causing case to move then in ignition slamming rearward and in turn over expanding in the chamber can/will happen. The ejector marks aren't from psi likely, but from bolt slap as the case comes back rearward to the bolt face. The phenomenon usually doesn't results in loose primer pockets however, that part is the one outlier of problems that doest match.

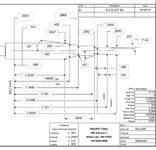

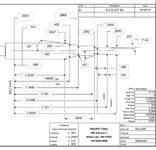

Ask the smith if you can get a reamer print, I'll post the old GAP 4s team reamer, it was commonly duplicated when the 65 Saum got popular. There are a lot of them out there with 0.120 long freebore as well.

If you were using Hornady, it's very soft in the web area, and your dies were likely sizing it adequately at the base. ADG brass is very hard in the web, and requires a pretty tight fitting die to get that area sized, if it's not getting sized enough, this is where "clickers" come from upon primary extraction opening the bolt. You may need tighter dies with the ADG, rcbs matchmaster and bullet central micron are the tightest off the shelf dies I've going for saum and prc cases.

I've run both Hornady and ADG 65saum brass. The newer HDY stuff is actually pretty decent, but doesn't handle pressure as well as ADG. I personally had no issues swapping direct loads from HDY to ADG.

Your lot of ADG brass may have thicker necks than Hornady mine did. I ended up turning the necks. Less neck clearance will increase pressure as well. Can you easily slide a case into a fired case neck? If you're having to force it in, your necks are tight.

What this sounds like is oversized brass to me tho. The above post about excessive bump causing case to move then in ignition slamming rearward and in turn over expanding in the chamber can/will happen. The ejector marks aren't from psi likely, but from bolt slap as the case comes back rearward to the bolt face. The phenomenon usually doesn't results in loose primer pockets however, that part is the one outlier of problems that doest match.

Ask the smith if you can get a reamer print, I'll post the old GAP 4s team reamer, it was commonly duplicated when the 65 Saum got popular. There are a lot of them out there with 0.120 long freebore as well.