sndmn11

"DADDY"

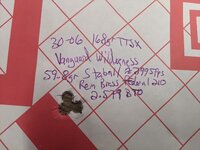

Same temperature as before, about 60deg, same range.

I went from the Hornaday brass to the Remington brass. SInce the Rem brass is a little smaller in capacity, I expected the velocity and pressure to increase, I just didn't know how much. I also seated them a tiny bit deeper which I think might also do the same.

30-06 Remington Brass, Fed 210 primer, BTO 2.579" = ~.111 jump (I was trying for .110) COAL 3.258" 168gr ttsx

57.4gr = 2868, 2891fps

57.7 = 2873, 2880

58.0 = 2909, 2896

58.2 = 2896, 2901

58.4 = 2905, 2915

58.6 = 2936, 2926

58.8 = 2931, 2944

60.0 = 2965, 2971

So, it looks like 58.1 should get me around 2800fps, and I am going to experiment with around 60.1 next go around. Bolt lift was all the same, brass and primers look fine.

I also loaded up some 6.5cm for a 20" Vanguard (2.295" to lands) and a 24" Vanguard (2.308" to lands).

Federal nickel brass with small primer pocket, winchester srp, BTO 2.208" = ~.087" and .100" jump respectively, 2.715" COAL, 120gr Nosler e-tip.

20"

44.7gr = 2856, 2839fps

45.0 = 2830, 2870

45.2 = 2838, 2866

45.4 = 2841, 2871

45.6 = 2886, 2874

24"

44.7gr = 2891, 2931fps

45.0 = 2938, 2947

45.2 = 2949, 2936

45.4 = 2945, 2959

45.6 = 2962, 2955

What is really interesting to me is that for both cartridges and all three rifles, at .1" jump, they are still longer than factory. For the 30-06 168ttsx, Barnes has a COAL at 3.240", I am at 3.258" with a .110" jump. The factory trophy copper cartridges that are the reason why we chose the e-tip for the 6.5cm, are about another .02" shorter than what I loaded up, but the Nosler load data has 2.775" for a COAL on their website. I also have some factory Hornady American Whitetail, and they are a similar length and BTO to the factory trophy copper. So, I don't know what to make of that. For reference, that factory trophy copper was going 2752 in the 20" rifle. I think I am going to experiment around the 45.6gr in that cartridge since in both rifles the two were not far apart.

I went from the Hornaday brass to the Remington brass. SInce the Rem brass is a little smaller in capacity, I expected the velocity and pressure to increase, I just didn't know how much. I also seated them a tiny bit deeper which I think might also do the same.

30-06 Remington Brass, Fed 210 primer, BTO 2.579" = ~.111 jump (I was trying for .110) COAL 3.258" 168gr ttsx

57.4gr = 2868, 2891fps

57.7 = 2873, 2880

58.0 = 2909, 2896

58.2 = 2896, 2901

58.4 = 2905, 2915

58.6 = 2936, 2926

58.8 = 2931, 2944

60.0 = 2965, 2971

So, it looks like 58.1 should get me around 2800fps, and I am going to experiment with around 60.1 next go around. Bolt lift was all the same, brass and primers look fine.

I also loaded up some 6.5cm for a 20" Vanguard (2.295" to lands) and a 24" Vanguard (2.308" to lands).

Federal nickel brass with small primer pocket, winchester srp, BTO 2.208" = ~.087" and .100" jump respectively, 2.715" COAL, 120gr Nosler e-tip.

20"

44.7gr = 2856, 2839fps

45.0 = 2830, 2870

45.2 = 2838, 2866

45.4 = 2841, 2871

45.6 = 2886, 2874

24"

44.7gr = 2891, 2931fps

45.0 = 2938, 2947

45.2 = 2949, 2936

45.4 = 2945, 2959

45.6 = 2962, 2955

What is really interesting to me is that for both cartridges and all three rifles, at .1" jump, they are still longer than factory. For the 30-06 168ttsx, Barnes has a COAL at 3.240", I am at 3.258" with a .110" jump. The factory trophy copper cartridges that are the reason why we chose the e-tip for the 6.5cm, are about another .02" shorter than what I loaded up, but the Nosler load data has 2.775" for a COAL on their website. I also have some factory Hornady American Whitetail, and they are a similar length and BTO to the factory trophy copper. So, I don't know what to make of that. For reference, that factory trophy copper was going 2752 in the 20" rifle. I think I am going to experiment around the 45.6gr in that cartridge since in both rifles the two were not far apart.

Last edited: