W.D. Crawford

Lil-Rokslider

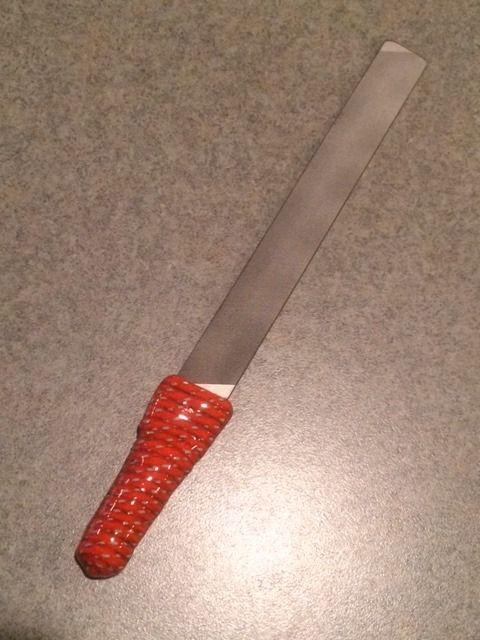

Well here it is two weeks and a day before season opens. I have spent the past few days sharpening some new Grizzly single bevel broadheads, and I have two to go, which is a good thing, as I have run out of hair on my arms, and I am now looking at other areas on my hide. I think I will stay away from my face, I'm ugly enough as it is. Maybe I can work on my chest hair, thin that down a little bit. Anyway I hope every one has a SAFE and successful season this year.