In bullets with both listed by VV in 223, N150 has a higher max load than N140, both are compressed. The 77 TMK does not have a N150 load listed, but setting max for N150 the same as for N140 one should be under the true max (N150 loads are first listed for 80 gr bullets). Both N140 and N150 need a drop tube to load at max and tapping the case. Clearly VV knows they are compressed loads and publishes it. I would need real data to accept a speculation that the compressed load is the issue with this combo. Plus, I had put several rounds of this load through the rifle, around 50, but I keep very poor logs.

Few hundred practice rounds of a different load later, I loaded up some more, I think I got through 7 of 30 before I noticed a blown primer. 3 primers had blown and the brass with blown pockets no longer fit in my RCBS shell holder.

I stopped shooting when I noticed the blown primers and pulled the remaining rounds apart and reloaded 0.9 gr lighter. Lost 80 fps, but no more issues. Load is still compressed and needs to be tapped to seat bullets consistently. Velocity loss with the drop in powder charge was consistent with my prior 10 round ladder in 0.5 gr increments to insure no pressure issues.

Velocity difference between the over pressure and load development loads was not impressive.

The load data is for 223 loads, not 5.56, but VV specifies data is for bolt guns and to use caution in auto loaders, so my guess is they are using a liberal max pressure between 60-65k psi.

A post I made the same day.

Post in thread 'Rokslide Special 223 recipe'

https://rokslide.com/forums/threads/rokslide-special-223-recipe.335947/post-3665127

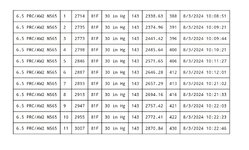

Screen shot of VV load data

View attachment 811265

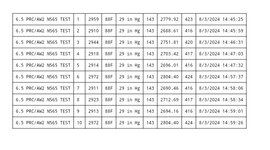

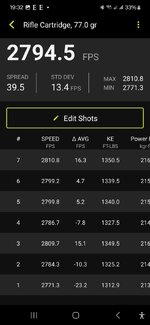

Chrono data from load development

View attachment 811268

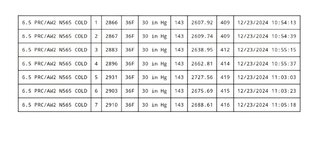

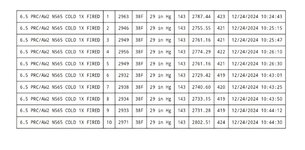

Chrono data from the blown primers

View attachment 811269

My big question, is why the confidence that fowling was not the issue? I have freely admitted that other things might have been the cause, but based on everything present so far in this thread, I find the idea that fowling can be ruled out to be unsound.

I have shot some 77 TMK loads that are above book max in different brass with N135 and not had an issue since this, and no cleaning. Which I find interesting and argues against (but doesn't prove) that cleaning was not the culprit.

Perhaps I just got the only 3 out of spec TMKs all in the same batch. Perhaps it was 3 pieces of bad Federal brass (but they had no issues shooting the factory 5.56 load). Perhaps it was bad powder (though the rest of that pound never caused an issue and I think I burned through 2 pounds from that lot).

Perhaps it was a combination of things, one of which was fowling. I don't have a pressure barrel to check the rounds in. Even if I recreate the load and blow primers, and it resolves with cleaning there will be plenty of unaccounted for variables if someone wants a different explanation.