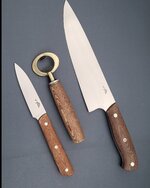

My father in law has a forge setup that he lets me use when we visit. My first knife I designed to have a long cutting bridge, 52100 steel, and sturdy enough to baton firewood or do anything else.

I like the blade shape and the general look, but the blade is far too thick and resulted in really poor cutting geometry. The sheath I also made myself and I’m pretty pleased with it.

I then tried to make a second knife to improve on the design, but I wasn’t careful enough between quenching and tempering and I broke the blade before I could finish.

Does anybody on here make their own knives? What steels do you like to work with, what blade shapes do you like, and what kind of grinder do you use?

My FIL lives 13 hours away, so I really need to get my own setup, so I’m curious to see what ya’ll use.

I like the blade shape and the general look, but the blade is far too thick and resulted in really poor cutting geometry. The sheath I also made myself and I’m pretty pleased with it.

I then tried to make a second knife to improve on the design, but I wasn’t careful enough between quenching and tempering and I broke the blade before I could finish.

Does anybody on here make their own knives? What steels do you like to work with, what blade shapes do you like, and what kind of grinder do you use?

My FIL lives 13 hours away, so I really need to get my own setup, so I’m curious to see what ya’ll use.