Kenny Hart

Lil-Rokslider

- Joined

- Feb 5, 2023

- Messages

- 109

Lucky enough to have both access to expensive equipment AND my boss lets me use it for personal projects. End result is looking pretty good:

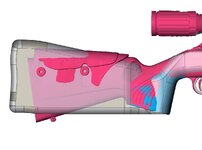

Modeled up the original Rokstock design for reference and grip angle (though I obviously don't have the real contour/palm swell:

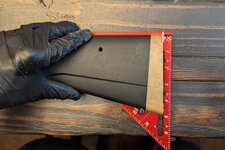

3D Scanned the factory grip and stock with a $70k 3D scanner:

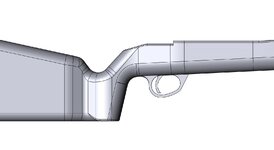

Modeled new grip with grip angle and 1.7" trigger reach, but with proper blend into the stock and pushing the Tikka grip radius forward:

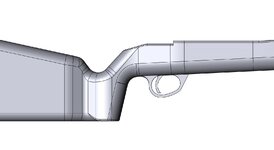

Added interior supports, though I beefed them up a hair. Not that it was needed, as I printed in PEEK on an industrial 3D printer so it's strong as shit and won't deflect in heat like other material I've experimented with in the past. I have a version with texture, but the smooth model looks nicer and the build lines in the printed part give a similar feel to traction tape, so I don't feel it's needed.

More to come, gotta do something about that silly factory recoil pad position!

Modeled up the original Rokstock design for reference and grip angle (though I obviously don't have the real contour/palm swell:

3D Scanned the factory grip and stock with a $70k 3D scanner:

Modeled new grip with grip angle and 1.7" trigger reach, but with proper blend into the stock and pushing the Tikka grip radius forward:

Added interior supports, though I beefed them up a hair. Not that it was needed, as I printed in PEEK on an industrial 3D printer so it's strong as shit and won't deflect in heat like other material I've experimented with in the past. I have a version with texture, but the smooth model looks nicer and the build lines in the printed part give a similar feel to traction tape, so I don't feel it's needed.

More to come, gotta do something about that silly factory recoil pad position!