Nomosendero

Lil-Rokslider

- Joined

- Apr 21, 2021

- Messages

- 212

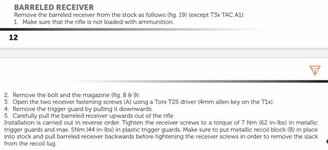

I recently made a trade and picked up a Tikka T3X Roughtech. The trigger is a bit stiff and I have ordered a MCarbo trigger spring. Does anyone know how many inch pounds is advised for the stock screws? I would ask Tikka but I figure it would turn into a lecture about the spring.

Thanks

Thanks